OTHER DRILLSTRING COMPONENTS

OTHER DRILLSTRING COMPONENTS

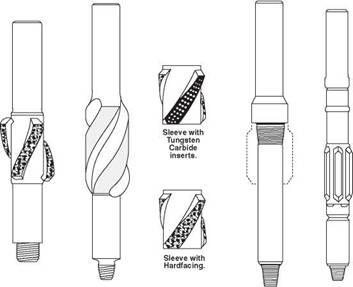

Stabilisers consist of a length of pipe with blades on the external surface. These blades may be either straight or spiral and there are numerous designs of stabilisers (Figure 8). The blades can either be fixed on to the body of the pipe, or mounted on a rubber sleeve (sleeve stabiliser), which allows the drillstring to rotate within it.

|

Figure 8 Stabilisers |

The function of the stabiliser depends on the type of hole being drilled. In this section we are concerned only with drilling vertical holes. Drilling deviated holes will be dealt with later. In vertical holes the functions of stabilisers may be summarised as follows:

• Reduce buckling and bending stresses on drill collars

• Allow higher WOB since the string remains concentric even in compression.

• Increase bit life by reducing wobble (i. e. all three cones loaded equally).

• Help to prevent wall sticking.

• Act as a key seat wiper when placed at top of collars.

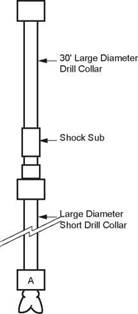

Generally, for a straight hole, the stabilisers are positioned as shown in Figure 9. Normally the stabilisers used will have 3 blades, each having a contact angle of 140 degrees (open design). When stabilisers begin to wear they become undergauge and are less efficient. Stabilisers are usually replaced if they become 1/2” undergauge (3/16” undergauge may be enough in some instances).

|

Figure 9 Stabiliser positions for straight hole drilling |

A roller reamer consists of stabiliser blades with rollers embedded into surface of the blade. The rollers may be made from high grade carburised steel or have tungsten carbide inserts (Figure 10). The roller reamer acts as a stabiliser and is especially useful in maintaining gauge hole. It will also ream out any potential hole problems (e. g. dog legs, key seats, ledges).

6.3 Shock sub (vibration dampener)

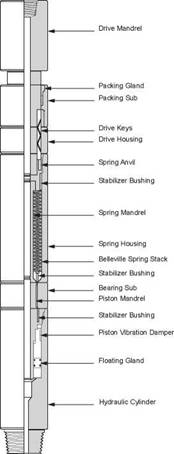

A shock sub is normally located above the bit to reduce the stress due to bouncing when the bit is drilling through hard rock. The shock sub absorbs the vertical vibration either by using a strong steel spring, or a resilient rubber element (Figure 11).

Subs are short joints of pipe which act as crossovers (i. e. connect components which cannot otherwise be screwed together because of differences in thread type or size).

The purpose of these tools is to deliver a sharp blow to free the pipe if it becomes stuck in the hole. Hydraulic jars are activated by a straight pull and give an upward blow. Mechanical jars are preset at surface to operate when a given compression load is applied and give a downward blow. Jars are usually positioned at the top of the drill collars.

|

|

Figure 10 Roller reamers

|

Figure 11 Shock sub |