Drill Pipe Selection

Drill Pipe Selection

The main factors considered in the selection of drillpipe are the collapse load, and the tensile load on the pipe. Burst pressures are not generally considered since these only occur when pressuring up the string on a plugged bit nozzle or during a DST, but it is very unlikely that the burst resistance of the pipe will be exceeded. Torsion need not be considered except in a highly deviated well.

Once the collapse and tension load have been quantified, the appropriated weight and grade of drillpipe can be selected.

Collapse Load

The highest external pressure tending to collapse the string will occur at the bottom when the string is run empty into the hole. (This only occurs when running a

|

if |

%

Drillstem Test — DST tool). If a non-return valve is run (preventing upward flow of fluid into the drillpipe) it is normally standard practice to fill up the pipe at regular intervals when running in. The highest anticipated external pressure on the pipe is given by

P = 0.052 x MW x TVD

c

where:

Pc = collapse pressure (psi)

MW = mud weight (ppg)

TVD = true vertical depth (ft) at which Pc acts

This assumes that there is no fluid inside the pipe to resist the external pressure (i. e. no back up). The collapse resistance of new and used drillpipe are given in Tables 11 and 12. The collapse resistance of the drillpipe is generally derated by a design factor (i. e. divide the collapse rating by 1.125). A suitable grade and weight of drill pipe must be selected whose derated collapse resistance is greater than Pc. This string must then be checked for tension.

The tensile resistance of drill pipe, as given in Table 11 and 12 is usually derated by a design factor (i. e. divide the tension rating by 1.15). The tension loading can be calculated from the known weights of the drill collars and drill pipe below the point of interest.

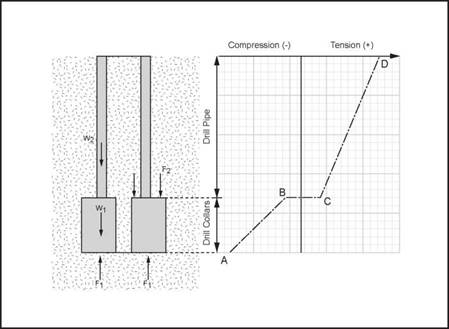

The effect of buoyancy on the drillstring weight, and therefore the tension, must also be considered. Buoyancy forces are exerted on exposed horizontal surfaces and may act upwards or downwards. These exposed surfaces occur where there is a change in cross-sectional area between different sections (Figure 16). By starting at the bottom of the string and working up to the top, the tension loading can be determined for each depth. This is represented graphically by the tension loading line (Figure 16).

If the drillpipe is to remain in tension throughout the drilling process, drillcollars will have to be added to the bottom of the drillstring. The bouyant weight of the drillcollars must exceed the bouyant force on the drillpipe and the neutral point shown in Figure 16 must be within the length of the drillcollars. The drillcollars required to provide WOB discussed above must be added to the drillcollars required to maintain the drillstring in tension.

When selecting the drillpipe, the maximum tensile load that the string could be subjected to will have to be considered. In addition to the design load calculated on the basis of the string hanging freely in the wellbore the following safety factors and margins are generally added:

• Design Factor — a design factor is generally added to the loading line calculated above (multiply by 1.3). This allows for extra loads due to rapid acceleration of the pipe.

• Margin of Overpull — a “margin of overpull” (MOP) is generally added to the loading line calculated above. This allows for the extra forces applied to the drill string when pulling on stuck pipe. The MOP is the tension in excess of the drill string weight which is exerted. The MOP may be 50,000 — 100,000 lbs.

|

Figure 16 Axial Load on the Drillstring |

• Safety Factor — a safety factor for slip crushing is generally added to the loading line calculated above. This allows for the interaction of hoopstress (Sh) caused by the slips and the tensile stress (St) caused by the weight of the string. This effect reduces the allowable tension load by a factor (Sh/St) which can be calculated as follows:

|

|

where:

D = O. D. of pipe (in)

L = length of slips (in)

K = lateral load factor

Slips are normally either 12 in. or 16 in. long, and for normally lubricated slips K =

2.0. Table 9 gives a direct result for Sh/St, but this assumes new pipe. If used pipe is being considered the actual D must be measured and Sh/St calculated from the above equation. Having obtained this factor it is applied to the tension loading line.

|

% |