ROTARY SYSTEM

ROTARY SYSTEM

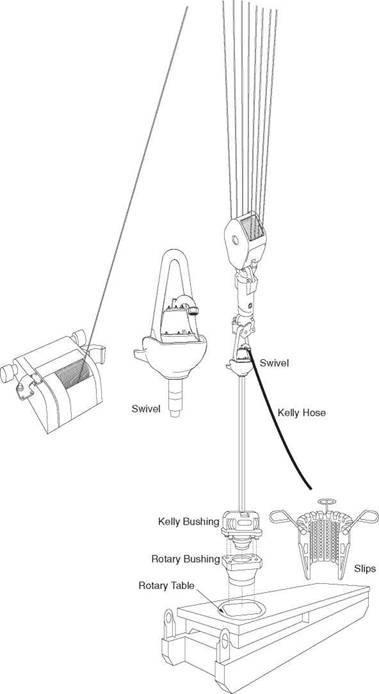

The rotary system is used to rotate the drillstring, and therefore the drillbit, on the bottom of the borehole. The rotary system includes all the equipment used to achieve bit rotation (Figure 9).

The swivel is positioned at the top of the drillstring. It has 3 functions:

• Supports the weight of the drill string

• Permits the string to rotate

• Allows mud to be pumped while the string is rotating

The hook of the travelling block is latched into the bail of the swivel and the kelly hose is attached to the gooseneck of the swivel.

The kelly is the first section of pipe below the swivel. It is normally about 40′ long, and has an outer hexagonal cross-section. It must have this hexagonal (or sometimes square) shape to transmit rotation from the rotary table to the drillstring. The kelly has a right hand thread connection on its lower [pin] end, and a left hand thread connection on its upper [box] end. A short, inexpensive piece of pipe called a kelly saver sub is used between the kelly and the first joint of drillpipe. The kelly saver sub prevents excessive wear of the threads of the connection on the kelly, due to continuous make-up and breakout of the kelly whilst drilling. Kelly cocks are valves installed at either end of the kelly to isolate high pressures and prevent backflow from the well if an influx occurs at the bottom of the well. The rotary table is located on the drill floor and can be turned in both clockwise and anti-clockwise directions. It is controlled from the drillers console. This rotating table has a square recess and four post holes. A large cylindrical sleeve, called a master bushing, is used to protect the rotary table.

The torque from the rotary table is transmitted to the kelly through the four pins on a device which runs along the length of the kelly, known as the kelly bushing. The kelly bushing has 4 pins, which fit into the post holes of the rotary table. When power is supplied to the rotary table torque is transmitted from the rotating table to the kelly via the kelly bushing. The power requirements of the rotary table can be determined from:

|

|

|

|

|

Figure 9 Rotary system Institute of Petroleum Engineering, Heriot-Watt University |

|

|

P _ юТ

rt —

where,

P = Power (hp) ш = Rotary Speed (rpm) T = Torque (ft-lbf)

Slips are used to suspend pipe in the rotary table when making or breaking a connection. Slips are made up of three tapered, hinged segments, which are wrapped around the top of the drillpipe so that it can be suspended from the rotary table when the top connection of the drillpipe is being screwed or unscrewed. The inside of the slips have a serrated surface, which grips the pipe (Figure 9).

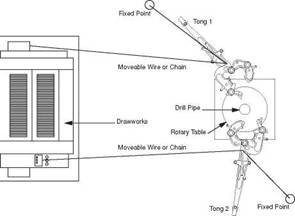

To unscrew (or “break”) a connection, two large wrenches (or tongs) are used. A stand (3 lengths of drillpipe) of pipe is raised up into the derrick until the lowermost drillpipe appears above the rotary table. The roughnecks drop the slips into the gap between the drillpipe and master bushing in the rotary table to wedge and support the rest of the drillstring. The breakout tongs are latched onto the pipe above the connection and the make up tongs below the connection (Figure 10). With the make-up tong held in position, the driller operates the breakout tong and breaks out the connection.

|

|

|

Figure 10 Tubing makeup and breakout |

|

003101310101310102020131010131 003101310101310102020131010131 |

To make a connection the make-up tong is put above, and the breakout tong below the connection. This time the breakout tong is fixed, and the driller pulls on the make-up tong until the connection is tight. Although the tongs are used to break or tighten up a connection to the required torque, other means of screwing the connection together, prior to torquing up, are available:

• For making up the kelly, the lower tool joint is fixed by a tong while the kelly is rotated by a kelly spinner. The kelly spinner is a machine which is operated by compressed air.

• A drillpipe spinner (power tongs) may be used to make up or backoff a connection (powered by compressed air).

• For making up some subs or special tools (e. g. MWD subs) a chain tong is often used.