Summary of One Circulation Method

Summary of One Circulation Method

the underlying principle of the one circulation method is that bottom hole pressure, Pbh is maintained at a level greater than the formation pressure throughout the operation, so that no further influx occurs. This is achieved by adjusting the choke, to keep the standpipe pressure on a planned profile, whilst circulating the required mudweight into the well. A worksheet may be used to carry out the calculations in an orderly fashion and provide the required standpipe pressure profile. While the choke is being adjusted the operator must be able to see the standpipe pressure gauge and the annulus pressure gauge. Good communication between the choke operator and the pump operator is important.

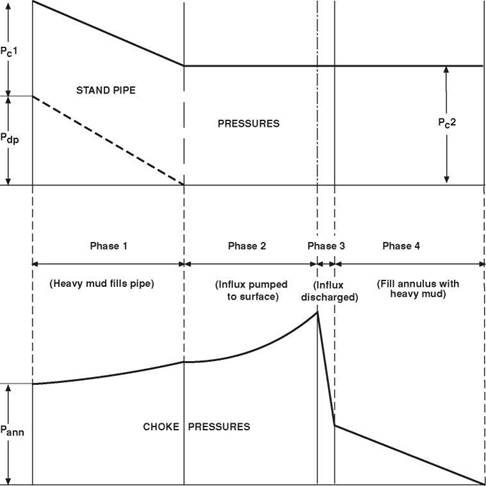

Figure 17 shows the complete standpipe and annulus pressure profiles during the procedure. Notice that the maximum pressure occurs at the end of phase II, just before the influx is expelled through the choke, in the case of a gas kick.

Safety factors are sometimes built into the procedure by:

• Using extra back pressure (200 psi) on the choke to ensure no further influx occurs. The effect of this is to raise the pressure profiles in Figure 16 by 200 psi.

• using a slightly higher mud weight. Due to the uncertainties in reading and calculating mud densities it is sometimes recommended to increase mud weight by 0.5 ppg more than the calculated kill weight. this will slightly increase the value of Pc2, and mean that the shut in drill pipe pressure at the end of phase I will be negative. Whenever mud weight is increased care should be taken not to exceed the fracture pressure of the formations in the openhole. (An increase of 0.5 ppg mud weight means an increased hydrostatic pressure of 260 psi at 10000ft). Some so-called safety margins may lead to problems of overkill.

|

Pressures versus Time

Figure 17 Summary of standpipe and annulus pressure during the "one circulation" method |

|

% |