API Couplings

API Couplings

The API provides specifications for three types of casing couplings: round thread, buttress thread and extreme-line coupling.

API Round Thread Coupling

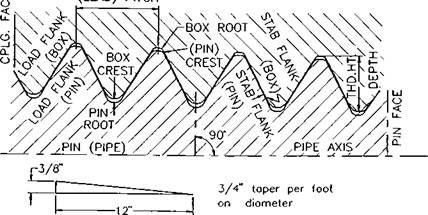

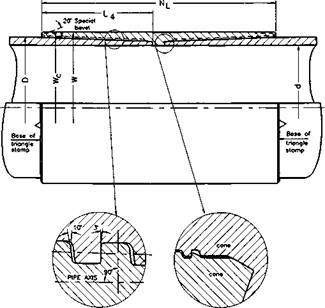

Eight API Round threads with a taper of | in./ft are cut per inch on diameter for all pipe sizes. The API Round thread has a V-shape with an included angle of 60° (Fig. 1.10), and thus the thread roots and crests are truncated with a radius. When the crest of one thread is mated against the root of another, there exists a clearance of approximately 0.003-in. which provides a leak path. In practice, a special thread compound is used when making up two joints to prevent leakage. Pressure created by the flank interface due to the makeup torque provides an additional seal. This pressure must be greater than the pressure to be contained.

API Round thread couplings are of two types: short thread coupling (STC) and long thread coupling (LTC). Both STC and LTC threads are weaker than the pipe body and are internally threaded. The LTC is capable of transmitting a higher axial load than the STC.

|

( FADl Р1ТГН

Fig. 1.10: Round thread casing configuration. (After API RP 5B1, 1988.) API Buttress Thread Coupling |

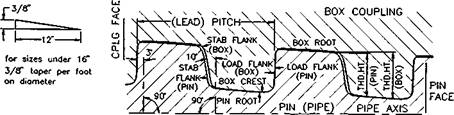

A cross-section of a API Buttress coupling is presented in Fig. 1.11. Five threads are cut in one inch on the pipe diameter and the thread taper is | in./ft for casing sizes up to 7| in. and 1 in./ft. for sizes 16 in. or larger. Long coupling, scjuare shape and thread run-out allow the API Buttress coupling to transmit higher axial load than API Round thread. The API Buttress couplings, however, depend on similar types of seal to the API Round threads. Special thread compounds are used to fill the clearance between the flanks and other meeting parts of the threads. Seals are also provided by pressure at the flanks, roots and crests during the making of a connection. In this case, tension has little effect on sealing, whereas compression load could separate the pressure flanks causing a spiral clearance between the pressure flanks and thereby permitting a leak. Frequent changes in load from tension to neutral to compression causes leaks in steam injection wells equipped with API Buttress couplings.

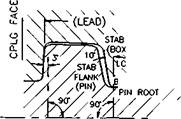

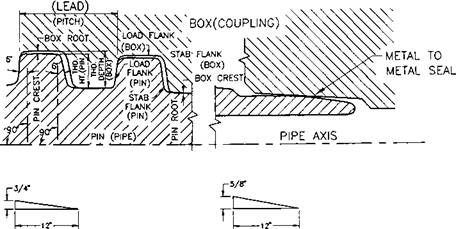

A modified buttress thread profile is cut on a taper in some proprietary connections to provide additional sealing. For example, in a Vallourec VAM casing coupling, the thread crest and roots are flat and parallel to the cone. Flanks are 3° and 10° to the vertical of the pipe axis, as shown in Fig. 1.12. and 5 threads per inch are on the axis of the pipe. Double metal-to-metal seals are provided at the pin end by incorporating a reverse shoulder at the internal shoulder (Fig. 1.12), which is resistant to high torque and allows non-turbulent flow of fluid.

Metal-to-metal seals, at the internal shoulder of VAM coupling, are affected most by the change in tension and compression in the pipe. When the makeup torque is applied, the internal shoulder is locked into the coupling, thereby creating tension in the box and compression in the pin. If tensile load is applied to the connection, the box will be elongated further and the compression in the pin will

|

|

|

Fig. 1.11: (a) API Buttress thread configuration for 13| in. outside diameter and smaller casing; (b) API Buttress thread configuration for 16 in. outside diameter and larger casing. (After API RP 5B1, 1988.) |

|

|

|

BOX COUPLING PITCH VH 4 4 4 4 4 4 4 \v FIANK x B0X rootn ,)44X^L, S .ОАО FLANK x |

|

(вох)-Г7^к IPX CRE? Tf,^K |

|

//PIN (PIPE) |

|

|

|

|

|

for sizes 16" and larger 1" taper per foot on diameter |

|

Fig. 1.12: Vallourec VAM casing coupling. (After Rabia, 1987; courtesy of Graham & Trotman) |

|

|

For sizes 7 5/8” and smaller For sizes larger than 7 5/8

1 1/2" taper per foot on 1 1/4” taper per foot on

diameter 6 pitch thread diameter 5 pitch thread

Fig. 1.13: API Extreme-line casing thread configuration. (After API RP 5B1. 1988.)

be reduced due to the added load. Should the tensile load exceed the critical value, the shoulders may separate.

API Extreme-line Thread Coupling

API Extreme-line coupling differs from API Round thread and API Buttress thread couplings in that it is an integral joint, i. e., the box is machined into the pipe wall. With integral connectors, casing is made internally and externally upset to compensate for the loss of wall thickness due to threading. The thread profile is trapezodial and additional metal-to-metal seal is provided at the pin end and external shoulder. As a result, API Extreme-line couplings do not require any sealing compound, although the compound is still necessary for lubrication. The metal-to-metal seal at the external shoulder of the pin is affected in the same way as VAM coupling when axial load is applied.

In an API Extreme—line coupling, 6 threads per inch are cut on pipe sizes of 5 in. to 7| in. with l| in./ft of taper and 5 threads per inch are cut on pipe sizes of 8| in. to 10! in. with in./ft of taper. Figure 1.13 shows different design features of API Extrem^line coupling.