Welded Pipe

Welded Pipe

In the continuous electric process, pipe with one longitudinal seam is produced by electric flash or electric resistance welding without adding extraneous metal. In the electric flash welding process, pipes are formed from a sheet with the desired dimensions and welded by simultaneously flashing and pressing the two ends. In the electric resistance process, pipes are manufactured from a coiled

|

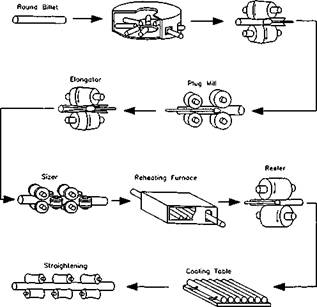

Rotory Heoting Furnoce Piercer

Fig. 1.3: Plug Mill Rolling Process for Kawasaki’s 7— 161 in. pipe. (Courtesy of Kawasaki Steel Corporation.) |

sheet which is fed into the machine, formed and welded by electric arc (Fig. 1.4). Pipe leaving the machine is cut to the desired length. In both the electric flash and electric arc welding processes, the casing is passed through dies that deform it sufficiently to exceed the elastic limit, a process which raises the elastic limit in the direction stressed and reduces it somewhat in the perpendicular direction: Bauchinger effect. Casing is also cold-worked during manufacturing to increase its collapse resistance.