Bending Moments in String Design

Bending Moments in String Design

A useful parameter when considering bending of the drillstring is the:

section modulus = I Moment of Inertia

C External radius of tube

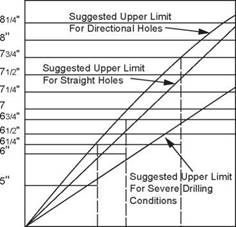

Field results have shown that if the ratio of section modulus between various string components is kept below 5.5 the failure rate is reduced. The section modulus ratio for a variety of drillpipe sizes is given in Table 8. In larger holes, or more severe drilling conditions, the ratio should be kept below 3.5 (Table 10). Essentially these guidelines will eliminate abrupt changes in cross sectional area throughout the drillstring. The selection of suitable HWDP’s to run above collars is simplified by Figure 16, which gives guidelines based on the extent of deviation in the hol

|

О |

|

% |

|

31/2" 4" 41/2" 5" |

Heavy Weight Drillpipe Size

Figure 15 Typical BHAs for straight hole drilling

|

Section Modulus Values |

||

|

Pipe O. D. inches |

Nominal pipe weight pounds per foot |

I/C |

|

23/8 |

4.85 |

0.66 |

|

6.65 |

0.87 |

|

|

27/8 |

6.85 |

1.12 |

|

10.40 |

1.60 |

|

|

31/2 |

9.50 |

1.96 |

|

13.30 |

2.57 |

|

|

15.50 |

2.92 |

|

|

4 |

11.85 |

2.70 |

|

14.00 |

3.22 |

|

|

15.70 |

3.58 |

|

|

41/2 |

13.75 |

3.59 |

|

216.60 |

4.27 |

|

|

20.00 |

5.17 |

|

|

5 |

19.50 |

5.71 |

|

25.60 |

7.25 |

|

Table 8 I/C Data for drillstring components |