Bent Sub and Mud Motor

Bent Sub and Mud Motor

The most commonly used technique for changing the trajectory of the wellbore uses a piece of equipment known as a “bent sub” (Figure 6) and a Positive Displacement (mud) motor. A bent sub is a short length of pipe with a diameter which is approximately the same as the drillcollars and with threaded connections on either end. It is manufactured in such a way that the axis of the lower connection is slightly offset (less than 3 degrees) from the axis of the upper connection. When made up into the BHA it introduces a “tilt angle” to the elements of the BHA below it and therefore to the axis of the drillbit. However, the introduction of a bent sub

|

|

|

|

into the BHA means that the centre of the bit is also offset from the centre line of the drillstring above the bent sub and it is not possible therefore to rotate the drillbit by rotating the drillstring from surface. Even if this were possible, the effect of the tilt angle would of course be eliminated since there would be no preferential direction for the bit to drill in.

Axis of drill string (non-magnetic collar)

|

|

Figure 6 Bent Sub

The bent sub must therefore be used in conjunction with a Positive Displacement Motor, PDM or a Drilling Turbine. The PDM is often called a mud motor

and is used in far more wells than the turbine. A detailed description, and some technical specifications, of mud motors and turbines is provided in the Appendix at the end of this chapter.

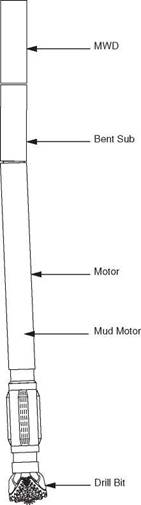

The mud motor is made up into the BHA of the drillstring below the bent sub, between the bent sub and drillbit (See Figure 7). When drilling fluid is circulated through the drillstring the inner shaft of the mudmotor, which is connected to the bit, rotates and therefore the bit rotates. It is therefore not necessary to rotate the entire drillstring from surface if a mud motor is included in the BHA. Mud motors and turbines are rarely used when not drilling directionally because they are expensive pieces of equipment and do wear out.

|

Figure 7 BHA with bent sub and mudmotor |

|

% |

A scribe line is marked on the inside of the bend of the bent sub, and this indicates the direction in which the bit will drill (this direction is known as the “tool face”). A directional surveying tool (quite often an MWD tool) is generally run as part of the BHA, just above the bent sub so that the trajectory of the well can be checked periodically as the well is deviating.

The bent sub and PDM can of course only be used in the build up or drop off portion of the well since the bit will continue to drill in the direction of the tilt angle as long as the bent sub is in the assembly and the mud motor is being used to rotate the bit. This leads to the major disadvantage of using a bent sub and PDM to change the trajectory of the well.

When drilling a well, the “conventional” assembly (without bent sub and mud motor) used to drill the straight portion of the well must be pulled from the hole and the bent sub and PDM assembly run in hole before the well trajectory can be changed. The bent sub and motor will then be used to drill off in a particular direction. When the well is drilling in the required direction (inclination and azimuth), the bent sub and PDM must then be pulled and the conventional assembly re-run. Otherwise the

drillbit would continue to change direction. This is a very time consuming operation (taking approximately 8 hrs at 10,00 ft depth for each trip out of, and into, the hole). Remember however that the build up section of a well can be 1-2000 ft long depending on the build up rate (typically 1-3 degrees/100ft) and the required inclination and therefore the bent sub and mud motor will be, depending on the rate of penetration, in the well for quite a long time time.