Directional Bottom Hole Assemblies (BHA)

Directional Bottom Hole Assemblies (BHA)

A conventional rotary drilling assembly is normally used when drilling a vertical well, or the vertical or tangent sections of a deviated well. When using a steerable assembly in a deviated well it is of course possible to drill the tangent sections of the well with the steerable assembly.

The BHA of the conventional assembly can also be designed in such a way as to result in an increase or decrease in the inclination of the wellbore but it is very difficult to predict the rate at which the angle will increase or decrease with a conventional BHA and therefore this technique is not widely used today.

The tendency of a conventional BHA to result in an increase or decrease in hole angle is a function of the flexibility of the BHA. Since all parts of the drillstring are flexible to some degree (even large, heavy drill collars) the BHA will bend when weight is applied to the bit. This will introduce a tilt angle at the bit. The magnitude and orientation of the tilt angle will depend on the stiffness of the drillcollars, the WOB and the number and position of the stabilizers in the BHA. A great deal of research was conducted in the 1960s and 70s, in an attempt to predict the directional tendencies of BHAs with but it is very difficult to predict the impact of the above variables on the rate at which the angle will increase or decrease and therefore this technique is not widely used today.

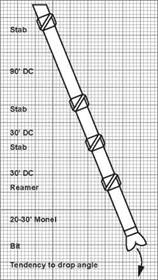

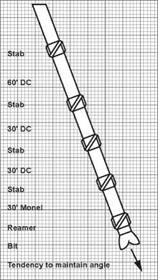

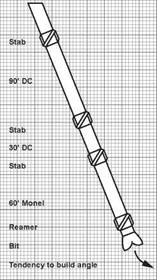

(a) Packed Hole (b) Pendulum (c) Fulcrum

|

|

|

|

|

|

Figure 13 Directional BHA’s

Three types of drilling assemblies have been used in the past to control the hole deviation: