Drilling Cost Estimates

Drilling Cost Estimates

Before a drilling programme is approved it must contain an estimate of the overall costs involved. When drilling in a completely new area with no previous drilling data available the well cost can only be a rough approximation. In most cases however, some previous well data is available and a reasonable approximation can be made.

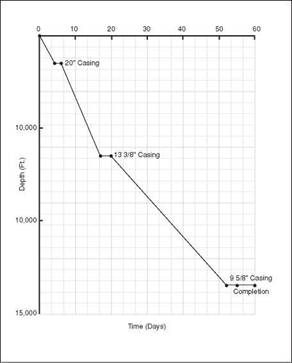

A typical cost distribution for a North sea Well is Shown in Table 2. Some costs are related to time and are therefore called time-related costs (e. g. drilling contract, transport, accommodation). Many of the consumable items (e. g. casing, cement) are related to depth and are therefore often called depth-related costs. These costs can be estimated from the drilling programme, which gives the lengths or volumes required. Some of the consumable items such as the wellhead will be a fixed cost. The specialised services (e. g. perforating) will be a charged for on the basis of a service contract which will have been agreed before the service is provided. The pricelist associated with this contract will be a function of both time and depth and the payment for the service will be made when the operation has been completed. For wells drilled from the same rig under similar conditions (e. g. platform drilling) the main factor in determining the cost is the depth, and hence the number of days the well is expected to take. Figure 10 shows a plot of depth against days for wells drilled from a North Sea platform. It is interesting to note that of the total time spent drilling a well less than half is spent actually rotating on bottom (Table 3)

|

% |

|

Breakdown of Well Costs |

||

|

($1000) |

( %) |

|

|

Wellhead |

105 |

1.1 |

|

Flowline and surface equipment |

161 |

1.7 |

|

Casing and downhole equipment |

1465 |

15.5 |

|

Sub- total |

1731 |

18.3 |

|

Drilling contractor |

2061 |

21.8 |

|

Directional drilling/surveying |

319 |

3.4 |

|

Logging/testing/perforating |

603 |

6.4 |

|

Mud processing/chemicals |

858 |

9.1 |

|

Cementing |

288 |

3.0 |

|

Bits |

282 |

3.0 |

|

Sub-total |

4411 |

46.7 |

|

Transport |

1581 |

16.7 |

|

Equipment rental |

391 |

4.1 |

|

Communications |

120 |

1.3 |

|

Mobilisation |

686 |

7.3 |

|

Power and fuel |

225 |

2.4 |

|

Supervision |

300 |

3.2 |

|

Sub-total |

3303 |

35.0 |

|

Total well cost |

$9,445,000 |

|

Table 2 Breakdown of well costs |

|

Time breakdown for a North Sea well (fixed platform) |

|||

|

HOURS |

% |

||

|

Drill |

552.0 |

41.9 |

|

|

Trips/Lay Down Drill Pipe |

195.0 |

14.8 |

|

|

Directional Surveys |

104.0 |

7.9 |

|

|

Core/Circ. Samples |

91.5 |

6.9 |

|

|

Guide Base/Conductor |

60.0 |

4.6 |

|

|

Wash/Ream/Clean Out Borehole |

59.0 |

4.5 |

|

|

Lost Time |

49.5 |

3.8 |

|

|

Run Casing/Tubing/Packer |

37.5 |

2.8 |

|

|

Nipple down, up/Run Riser |

37.0 |

2.8 |

|

|

Log/Set Packer/Perforate |

26.5 |

2.0 |

|

|

Test Bops/Wellhead |

25.0 |

1.9 |

|

|

Rig Maintenance |

20.5 |

1.6 |

|

|

Circ. & Cond./Displace Mud |

20.5 |

1.5 |

|

|

Fishing/Milling |

20.0 |

1.5 |

|

|

Cement/Squeeze/WOC |

18.0 |

1.4 |

|

|

Rig Down/Move/Rig Up |

2.5 |

0.2 |

|

|

TOTAL |

1318.5hrs (55 days) |

100.0 |

|

Table 3 Time breakdown for a North Sea well (fixed platform) |

More sophisticated methods of estimating well costs are available through specially designed computer programmes. Whatever method is used to produce a total cost some allowance must be made for unforeseen problems. When the estimate has been worked out it is submitted to the company management for approval. This is usually known as an AFE (authority for expenditure). Funds are then made available to finance the drilling of the well within a certain budget. When a well exceeds its allocated funds a supplementary AFE must be raised to cover the extra costs.

Exercise 1 Cost and Time Distributions

Rank the major cost elements in the development of the Brae Field given in Table 1 and consider the ways in which the costs distribution might change with a bigger or smaller field.

Consider how the costs associated with a well (Table 2) are related to the time distribution (Table 3) for a well.

Exercise 2 The Drilling Process

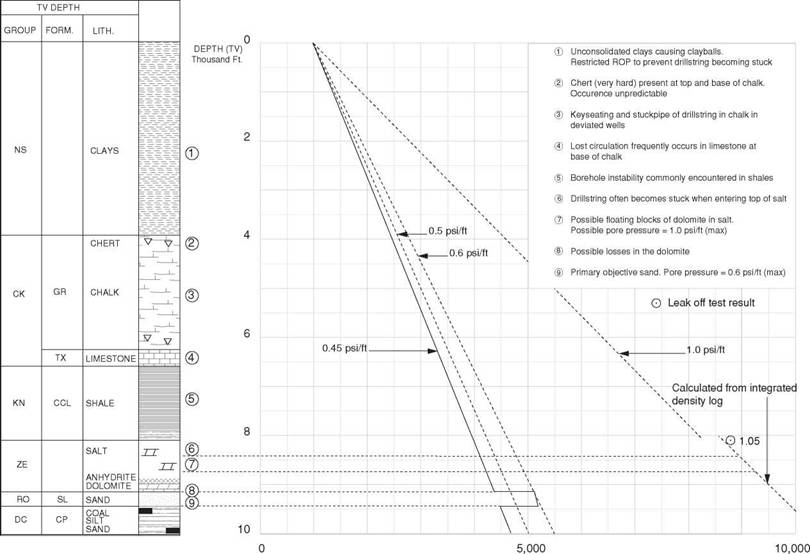

You are required to drill a well into the Rotliegende sandstone (ROSL) shown on the attached geological cross section (Appendix 1). Consider the following aspects of the drilling operation and how you would drill the well.:

a) the rock penetration process

— the rock cutting mechanism/tool

— the transmission of energy to the cutting tool

— the removal of debris from the face of the cutting tool and the borehole

b) the stability/integrity of the borehole

— potential causes of instability

— potential consequences of instability

— means of preventing/mitigating problems associated with instability

c) the safety of the operation

— the greatest source of risk during the drilling operation

d) data and its acquisition

— data relevant to the drilling process

— data relevant to evaluating the potential oil and gas production of the formations

e) the surface equipment requirements

|

Figure 10 Drilling Time/Depth chart |

|

Overview of Drilling Operations |

|

Bottom Hole Pressure, psi |

|

Institute of Petroleum Engineering, Heriot-Watt University |

|

Q. Q. < |

|

>< Q |

1. INTRODUCTION

2. POWER SYSTEM

3. CIRCULATING SYSTEM

Round Trip Operations Drilling Ahead Running Casing Short Trips

4. CIRCULATING SYSTEM

Duplex Pumps Triplex Pumps

|

5. ROTARY SYSTEM

|

6. WELL CONTROL SYSTEM

6.1 Detecting a kick

6.2 Closing in the Well

6.3 Circulating out a kick

7. WELL MONITORING SYSTEM

Having worked through this chapter the student will be able to:

General:

• Describe the six major sub-systems of a drilling rig and the function of each system.

Power System:

• Describe the power system on a drilling rig.

Hoisting system:

• Identify the names of each of the component parts of the hoisting system and state its purpose.

• Describe the slip and slip and cut operation.

• Calculate the tension on the drilling line and select an appropriate line diameter for a particular application.

• Calculate the load on the derrick when running or pulling a string or casing or drillpipe.

• Calculate the work done on a drilling line.

Circulating System:

• Describe the functions of the drilling fluid.

• Identify the names of each of the component parts of the circulating system and state its purpose.

• Describe the difference between duplex and triplex pumps.

• Calculate the volumetric output of a triplex and duplex pump.

• Calculate the horsepower requirements for the mud pumps.

Rotary System:

• Identify the names of each of the component parts of the rotary system and state its purpose.

• State the benefits of the topdrive system.

• Describe the procedure for running and pulling out of hole.

• Describe the procedure for making a connection.

Well Control System:

• Identify the names of each of the component parts of the well control system and state its purpose.