Equipment Used for Squeeze Cementing

Equipment Used for Squeeze Cementing

The high pressure and low pressure squeeze operations can be conducted with or without packers.

(a) Bradenhead squeeze

This technique involves pumping cement through drill pipe without the use of a packer (Figure 20). The cement is spotted at the required depth. The BOPs and the annulus are closed in and displacing fluid is pumped down, forcing the cement into the perforations, since it cannot move up the annulus. This is the simplest method of placing and squeezing cement, but has certain disadvantages:

• It is difficult to place the cement accurately against the target zone

• It cannot be used for squeezing off one set of perforations if other perforations are to remain open

• Casing is pressured up, and so squeeze pressure is limited by burst resistance

A Bradenhead squeeze is only generally used for a low-pressure squeeze job.

|

Spot cement |

Apply squeeze pressure

Schematic of Bradenhead squeeze technique normally used on low pressure forma Cement is circulated into place down drill pipe (left), then the wellhead, or BOP, is c (centre) and squeeze pressure is applied. Reverse circulating through perforations removes excess cement, or the plug can be drilled out.

Reverse circulate

Figure 20 Bradenhead technique

(b) Squeeze using a packer

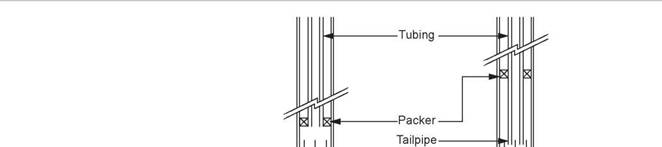

The use of a packer makes it possible to place the cement more accurately, and apply higher squeeze pressures. The packer seals off the annulus, but allows communication between drill pipe and the wellbore beneath the packer. (Figure 21)

|

|

|

Figure 21 Squeeze cementing using a packer with or without a tailpipe |

Two types of packer may be used in this type of operation:

(i) Drillable packer (cement retainer)

This type of packer contains a back pressure valve which will prevent the cement flowing back after the squeeze. These are mainly used for remedial work on primary cement jobs, or to close off water producing zones. The packer is run on drill pipe or wireline and set just above or between sets of perforations. When the cement has been squeezed successfully the drill pipe can be removed, closing the back pressure valve. The advantages of these packers are:

• Good depth control

• Back pressure valve prevents cement back flowing

• Drill pipe recovered without disturbing cement

The major disadvantage is that they can only be used once then drilled out.

(ii) Retrievable packer (cement retainer)

These can be set and released many times on one trip. This makes them suitable for repairing a series of casing leaks or selectively squeezing off sets of perforations. By-pass ports in the packer allow annular communication, but these ports are closed during the squeeze job. When the packer is released there may be some backflow, and the cement filter cake may be disturbed. If this happens the packer should be re-set and the squeeze pressure applied until the cement sets.

The basic procedure for squeezing with a retrieveable packer is:

1. run the packer on drillpipe and set it at required depth with by-pass open

2. pump the cement slurry (keep back pressure on annulus to prevent cement falling

The packer setting depth should be considered carefully. If positioned too high above the perforations the slurry will be contaminated by the wellbore fluids and large volumes of fluid from below the packer will be pumped into the formation

ahead of the cement. If the packer is set too low it may become stuck in the cement. Generally the packer is set 30 — 50 ft above the perforations.

Sometimes a tail pipe is used below the packer to ensure that only cement is squeezed into the perforations, and there is less chance of getting stuck (Figure 21). Bridge plugs are often set in the wellbore, to isolate zones which are not to be treated. They seal off the entire wellbore, and hold pressure from above and below. Bridge plugs can either be drillable or retrievable.

c^> Drill c^5

|

pipe |

Spacer

.Cement

|

|

|

Spacer and preflush Cement plug |

|

r |

|

. Scratch centralizer |

|

. Preflush |

|

Г |

|

Pull pipe slowly |

Condition mud rotation pipe

Displace cement and fluids

Spot balanced plug

Figure 22 Balanced Plug Cementation