MWD — GAMMA RAY TOOLS

MWD — GAMMA RAY TOOLS

The GR log is a long established part of formation evaluation. Gamma rays in the formation are emitted mainly by radioactive isotopes of Potassium, Thorium and Uranium. These elements occur primarily in shales, and so the GR log is a good shale indicator.

Apart from the obvious geological applications the GR log from an MWD system has important engineering applications (Table 3). There has been a big increase in the use of GR logs run in combination with the MWD directional tooltool

|

Generic Application |

Specific Application |

|

Geological |

Immediate indication of change in Lithology Picking Formation Tops, Coring Points Shaliness (Vclay) indicator Differentiate between cuttings and cavings Correlation with other wells |

|

Engineering |

Selecting Casing Points Identifying troublesome formations Identifying drilling problems Running checklog prior to EWL |

|

Table 3 MWD Application |

Since any change in lithology must be known as quickly as possible the GR sensor should be placed as near the bit as possible, below the directional sensors. Running an MWD GR log has the added problems of rigging up a depthtracking system.

|

|

The type of sensors used to detect gamma rays must be both robust and efficient. The most robust sensor is the Geiger-Muller tube, but unfortunately it will only detect a small percentage of the rays being emitted by the formation. A more sensitive but less rugged sensor, is the Scintillation counter. Both types are used in MWD GR tools but the scintillation counter is the more popular.

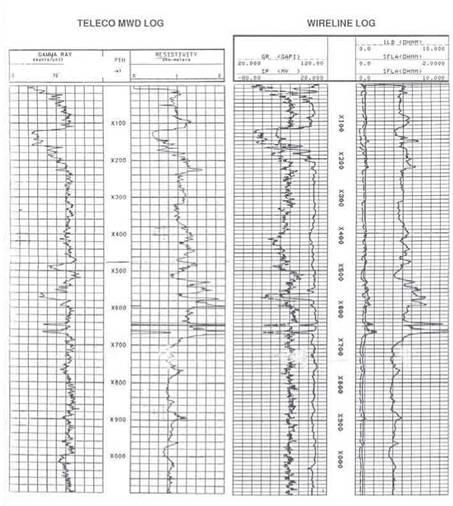

It is interesting to compare GR and Resistivity logs from an MWD tool with those obtained from wireline logging after the well has been drilled (Figure 6). Several points must be borne in mind when making these comparisons:

(i) The logging speeds are very different (wireline @ 1800 ft/h MWD @ 10 -100 ft/h). The resolution of the two logs will therefore be affected.

|

Figure 6 Comparison of MWD and Wireline Log |

(ii) Wellbore conditions may be different since the MWD log was made, e. g. cavings.

(iii) MWD log is made through a drill collar, so the attenuation of gamma rays will be greater.

(iv) Central position of the sensors may be different, especially in high angled holes.

Directional sensors and GR sensors are well established for MWD use. More sensors are being developed and the term LWD — Logging Whilst Drilling is now used to describe these tools.