Natural Diamond Bits

Natural Diamond Bits

The hardness and wear resistance of diamond made it an obvious material to be used for a drilling bit. The diamond bit is really a type of drag bit since it has no moving cones and operates as a single unit. Industrial diamonds have been used for many years in drill bits and in core heads (Figure 1).

|

|

The cutting action of a diamond bit is achieved by scraping away the rock. The diamonds are set in a specially designed pattern and bonded into a matrix material set on a steel body. Despite its high wear resistance diamond is sensitive to shock and vibration and therefore great care must be taken when running a diamond bit. Effective fluid circulation across the face of the bit is also very important to prevent overheating of the diamonds and matrix material and to prevent the face of the bit becoming smeared with the rock cuttings (bit balling).

The major disadvantage of diamond bits is their cost (sometimes 10 times more expensive than a similar sized rock bit). There is also no guarantee that these bits will achieve a higher ROP than a correctly selected roller cone bit in the same formation. They are however cost effective when drilling formations where long rotating hours (200-300 hours per bit) are required. Since diamond bits have no moving parts they tend to last longer than roller cone bits and can be used for extremely long bit runs. This results in a reduction in the number of round trips and offsets the capital cost of the bit. This is especially important in areas where operating costs are high (e. g. offshore drilling). In addition, the diamonds of a diamond bit can be extracted, so that a used bit does have some salvage value.

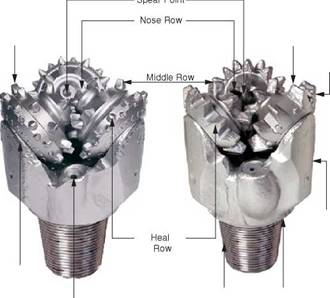

A new generation of diamond bits known as polycrystalline diamond compact (PDC) bits were introduced in the 1980’s (Figure 5). These bits have the same advantages and disadvantages as natural diamond bits but use small discs of synthetic diamond to provide the scraping cutting surface. The small discs may be manufactured in any size and shape and are not sensitive to failure along cleavage planes as with natural diamond. PDC bits have been run very successfully in many areas around the world. They have been particularly successful (long bit runs and high ROP) when run in combination with turbodrills and oil based mud.

A further development of the PDC bit concept was the introduction in the later 1980’s of Thermally Stable Polycrystalline (TSP) diamond bits. These bits are manufactured in a similar fashion to PDC bits but are tolerant of much higher temperatures than PDC bits.

|

|

|

Carbide Tooth Compact |

|

Shirttail Hardfacing |

|

_ Сгтлог |

|

Milled Tooth |

|

Guage Surface |

|

Shirttail |

|

Jet Nozzle |

|

Shank Shank Shoulder |

|

Figure 4 Elements of a rock bit (Courtesy of Hughes Christensen) |

|

|

|

|

Figure 5 Polycrystalline Compact (PDC) Bits (Courtesy of Hughes Christensen)

|

|

Roller Cone Bits and PDC Bits are the most widely used bits internationally and constitute virtually the entire bit market and therefore they are the only types of bits that will be discussed in detail in this section.