OFFSHORE DRILLING

OFFSHORE DRILLING

About 25% of the world’s oil and gas is currently being produced from offshore fields (e. g. North Sea, Gulf of Mexico). Although the same principles of rotary drilling used onshore are also used offshore there are certain modifications to procedures and equipment which are necessary to cope with a more hostile environment.

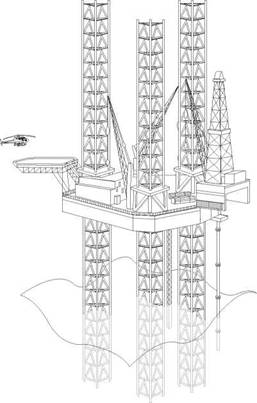

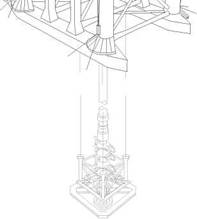

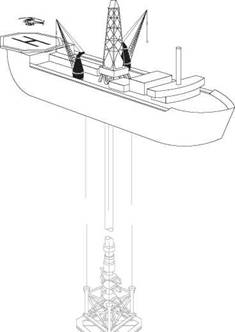

In the North Sea, exploration wells are drilled from a jack-up (Figure 6) or a semi — submersible (Figure 7) drilling rig. A jack-up has retractable legs which can be lowered down to the seabed. The legs support the drilling rig and keep the rig in position (Figure 6). Such rigs are generally designed for water depths of up to 350 ft water depth. A semi-submersible rig is not bottom supported but is designed to float (such rigs are commonly called “floaters”). Semi-submersibles can operate in water depths of up to 3500 ft. (Figure 7). In very deep waters (up to 7500 ft) drillships (Figure 8) are used to drill the well. Since the position of floating drilling rigs is constantly changing relative to the seabed special equipment must be used to

connect the rig to the seabed and to allow drilling to proceed. The equipment used to drill wells from these drilling rigs will be discussed at length in a subsequent chapter.

|

X |

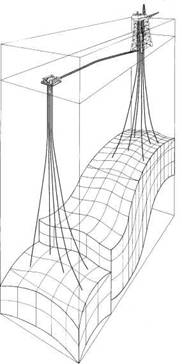

If the exploration wells are successful the field may be developed by installing large fixed platforms from which deviated wells are drilled (Figure 9). There may be up to 40 such wells drilled from one platform to cover an entire oilfield. For the very large fields in the North Sea (e. g. Forties, Brent) several platforms may be required. These deviated wells may have horizontal displacements of 10,000 ft and reach an inclination of 70 degrees or more. For smaller fields a fixed platform may not be economically feasible and alternative methods must be used (e. g. floating production system on the Balmoral field). Once the development wells have been drilled the rig still has a lot of work to do. Some wells may require maintenance (workovers) or sidetracks to intersect another part of the reservoir (re-drill). Some wells may be converted from producers to gas injectors or water injectors.

|

Figure 6 Jack-up rig |

|

|

|

Figure 7 Semi — submersible rig |

|

Figure 8 Drillship Institute of Petroleum Engineering, Heriot-Watt University |

|

Figure 9 Fixed platform (Steel Jacket) |

A well drilled from an offshore rig is much more expensive than a land well

drilled to the same depth. The increased cost can be attributed to several factors, e. g. specially designed rigs, subsea equipment, loss of time due to bad weather, expensive transport costs (e. g. helicopters, supply boats). A typical North Sea well drilled from a fixed platform may cost around $10 million. Since the daily cost of hiring an offshore rig is very high, operating companies are very anxious to reduce the drilling time and thus cut the cost of the well.