Procedure for Adding Drillpipe when Drilling Ahead

Procedure for Adding Drillpipe when Drilling Ahead

|

|

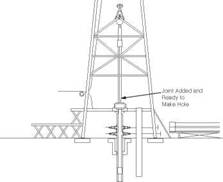

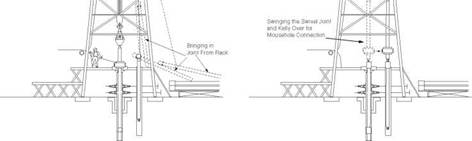

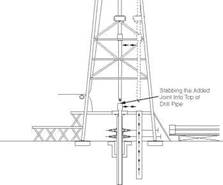

When drilling ahead the top of the kelly will eventually reach the rotary table (this is known as kelly down). At this point a new joint of pipe must be added to the string in order to drill deeper. The sequence of events when adding a joint of pipe is as follows (Figure 11):

|

|

|

|

Figure 11 Proceedure for adding drill pipe to the drillstring

1. Stop the rotary table, pick up the kelly until the connection at the bottom of the kelly saver sub is above the rotary table, and stop pumping.

2. Set the drillpipe slips in the rotary table to support the weight of the drillstring, break the connection between the kelly saver sub and first joint of pipe, and unscrew the kelly.

3. Swing the kelly over to the next joint of drillpipe which is stored in the mousehole (an opening through the floor near the rotary table).

4. Stab the kelly into the new joint, screw it together and use tongs to tighten the connection.

x

|

«? |

%

5. Pick up the kelly and new joint out of the mousehole and swing the assembly back to the rotary table.

6. Stab the new joint into the connection above the rotary table and make-up the connection.

7. Pick up the kelly, pull the slips and run in hole until the kelly bushing engages the rotary table.

8. Start pumping, run the bit to bottom and rotate and drill ahead.

This procedure must be repeated every 30ft as drilling proceeds.