Procedure for Pulling the Drillstring from the Hole

Procedure for Pulling the Drillstring from the Hole

|

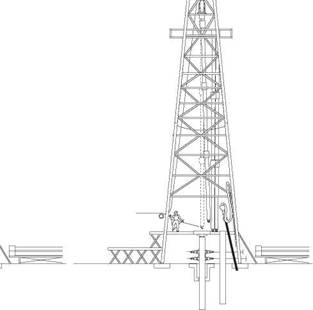

Figure 12 Procedure for pulling pipe from the hole |

When the time comes to pull out of the hole the following procedure is used (Figure 12):

1. Stop the rotary, pick up the kelly until the connection at the bottom of the kelly saver sub is above the rotary table, and stop pumping

2. Set the drillpipe slips, break out the kelly and set the kelly back in the rat-hole (another hole in the rig floor which stores the kelly and swivel when not in use)

3. Remove the swivel from the hook (i. e. kelly, kelly bushing, swivel and kelly hose all stored in rathole)

4. Latch the elevators onto the top connection of the drillpipe, pick up the drillpipe and remove the slips. Pull the top of the drillpipe until the top of the drillpipe is at the top of the derrick and the second connection below the top of the drillpipe is exposed at the rotary table. A stand (3 joints of pipe) is now exposed above the rotary table

5. Roughnecks use tongs to break out the connection at the rotary table and carefully swings the bottom of the stand over to one side. Stands must be stacked in an orderly fashion.

6. The Derrickman, on the monkey board, grabs the top of the stand, and sets it back in fingerboard.

When running pipe into the hole it is basically the same procedure in reverse.

On some rigs a mechanical device known as an iron roughneck may be used to make-up and break-out connections. This machine runs on rails attached to the rig floor, and is easily set aside when not in use. Its mobility allows it to carry out mousehole connections when the tracks are correctly positioned. The device consists of a spinning wrench and torque wrench, which are both hydraulically operated. Advantages offered by this device include controlled torque, minimal damage to threads (thereby increasing the service life of the drillpipe) and reducing crew fatigue.