Reduced Height of Mud Colom

Reduced Height of Mud Colom

During normal drilling operations the volume of fluid pumped into the borehole should be equal to the volume of mud returned and when the pumps are stopped the fluid should neither continue to flow from the well (this would indicate that a kick

%

|

X |

was taking place) nor should the level of the mud fall below the mud flowline. The latter can be observed by looking down the hole through the rotary table.

If the top of the mud drops down the hole then the height of the colom of mud above any particular formation is decreased and the borehole pressure at that point is decreased. It is therefore essential that the height of the colom of mud is continuously monitored and that if the colom of mud does not extend to surface then some action must be taken before continuing operations.

The mud colom height may be reduced by ;

• Tripping

• Swabbing

• Lost circulation

|

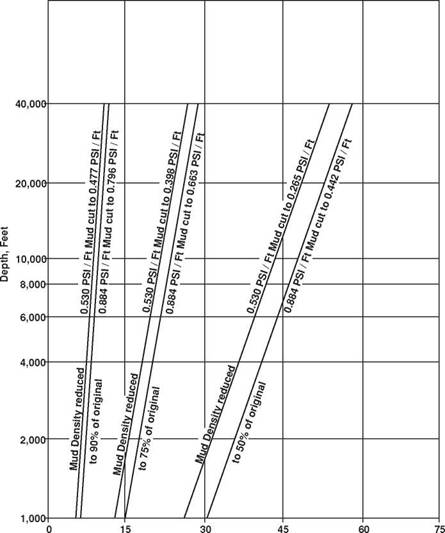

Change in BHP, PSI Figure 5 Reduction in bottom hole pressure due to observed surface reduction caused by gas influx |

a. Tripping :

The top of the colom of mud will fall as the drillpipe is pulled from the borehole when tripping. this will result in a reduction in the height of the colom of mud above any point in the wellbore and will result in a reduction in bottom hole pressure. The hole must therefore be filled up when pulling out of the hole. The volume of pipe removed from the borehole must be replaced by an equivalent volume of drilling fluid.

b. Swabbing :

Swabbing is the process by which fluids are sucked into the borehole, from the formation, when the drillstring is being pulled out of hole. this happens when the bit has become covered in drilled material and the drillstring acts like a giant piston when moving upwards. this creates a region of low pressure below the bit and formation fluids are sucked into the borehole. (The opposite effect is known as Surging, when the pipe is run into the hole).

The amount of swabbing will increase with:

• the adhesion of mud to the drillpipe

• the speed at which the pipe is pulled

• use of muds with high gel strength and viscosity

• Having small clearances between drillstring and wellbore

• A thick mud cake

• Inefficient cleaning of the bit to remove cuttings.

c. Lost Circulation :

Lost circulation occurs when a fractured, or very high permeability, formation is being drilled. Whole mud is lost to the formation and this reduces the height of the mud colom in the borehole. Lost circulation can also occur if too high a mud weight is used and the formation fracture gradient is exceeded. Whatever the cause of lost circulation it does reduce the height of the colom of mud in the wellbore and therefore the pressure at the bottom of the borehole. When the borehole pressure has been reduced by losses an influx, from an exposed, higher pressure, formation can occur. Losses of fluid to the formation can be minimised by :

• using the lowest practicable mud weight.

• Reducing the pressure drops in the circulating system therefore reducing the EcD of the mud

• Avoid pressure surges when running pipe in the hole.

• Avoid small annular clearances between drillstring and the hole.

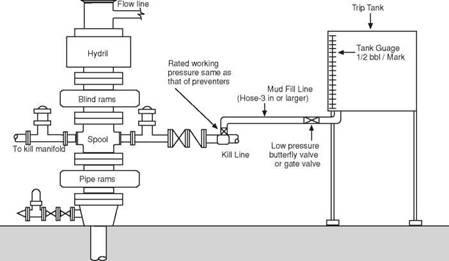

It is most difficult to detect when losses occur during tripping pipe into or out of the hole since the drillpipe is being pulled or run into the hole and therefore the level of the top of the mud colom will move up and down. A Possum Belly Tank (or trip tank) with a small diameter to height ratio is therefore used to measure the amount of mud that is used to fill, or is returned from, the hole when the pipe is pulled from, or run into, the hole respectively. As the pipe is pulled from the hole, mud from the trip tank is allowed to fill the hole as needed. Likewise when tripping in, the displaced mud can be measured in the trip tank ( Figure 6). the advantage of using a tank with a small diameter to height ratio is that it allows accurate measurements of relatively small volumes of mud.

%

|

|

Figure 6 Trip tank connected to BoP stack to closely monitor volume of mud

required for fill-up

When the drillpipe is pulled out the hole the volume of mud that must be pumped into the hole can be calculated from the following :

Length of Pipe x Displacement of Pipe

10 stands of 5", 19.5 lb/ft drillpipe would have a displacement of :

10 x 93 x 0.00734 bbl/ft. = 6.8 bbls.

Therefore, the mud level in the hole should fall by an amount equivalent to 6.8bbls of mud. If this volume of mud is not required to fill up the hole when 10 stands have been pulled from the hole then some other fluid must have entered the wellbore. This is a primary indicator of a kick.

Exercise 1 Impact of Mudweight and Hole Fillup on Bottomhole Pressure:

a. An 8 1/2” hole is drilled to 8000ft using mud with a density of 12 ppg. If the formation pore pressure at this depth was 4700 psi what would be the mud pressure overbalance, above the pore pressure.

b. If the mud density were 10 ppg what would be the overbalance?

c. If the fluid level in the annulus in a. above dropped to 200 ft due to inadequate hole fill up during tripping, what would be the effect on bottom hole pressure?