ROCK BIT EVALUATION

ROCK BIT EVALUATION

As each bit is pulled from the hole its physical appearance is inspected and graded according to the wear it has sustained. The evaluation of bits is useful for the following reasons:

• To improve bit type selection

• To identify the effects of WOB, RPM, etc., which may be altered to improve the performance of the next bit

• To allow drilling personnel to improve their ability to recognise when a bit should be pulled (i. e. to correlate the performance of a bit downhole with its physical appearance on surface)

• To evaluate bit performance and help to improve their design

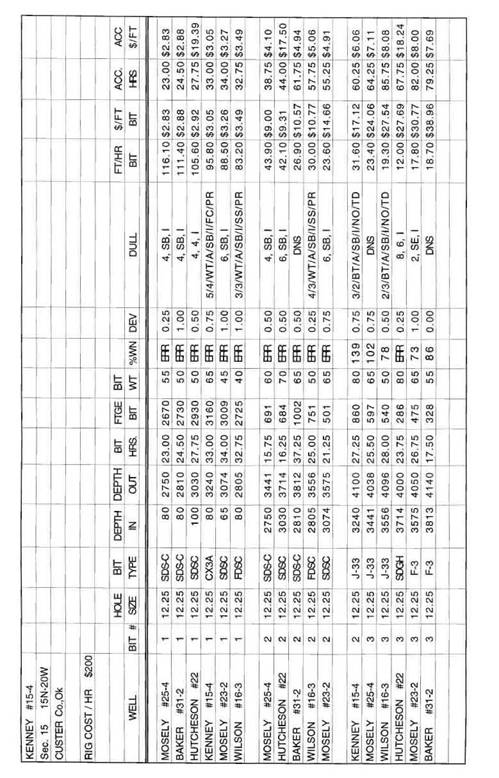

A bit record (Table 5) will always be kept by the operating company, drilling contractor and/or bit vendor. This bit record is used to store the following information about the bit after it has completed its run:

• The bit size type and classification

• The operating parameters

• The condition of the bit when pulled

• The performance of the bit

The IADC Dull Grading system has recently been revised (1987) so that it may be applied to all types of bit — roller cone or fixed cutter (PDC, Diamond). The

system is based on the chart shown in Figure 24 and will be described in terms of

each column :

Column 1 — Cutting Structure Inner Row (I) :

Report the condition of the cutting structure on the inner 2/3 rds of the bit for roller cone bits and inner 2/3 rds radius of a fixed cutter bit (Figure 24)

|

|

Table 5 Bit Record

|

Column 2 — Cutting Structure Outer Row (O) Report the condition of the cutting structure on the outer 1/3 rd of the bit for roller cone bits and outer 1/3 ids radius of a hxed cutter bit (Figure 24). In column 1 and 2 a linear scale from 0 to 8 is used to describe the condition of the cutting structure as follows |

|

Becurjtu |

IADC DULL BIT GRADING |

Securitu |

ssE/*y |

|

Гг? Li ‘ |

|

‘VqA |

|

|

|

CUTTING STRUCTURE |

BEARINGS’ |

GAGE |

OTHER OULI |

REASON |

|||

|

INNER |

OUTER |

DULL CHAP |

LOCATION |

SEALS |

CHAR. |

PULLED |

|

|

Ф |

© |

© |

© |

© |

® |

0 |

® |

|

> a О D Ј Q Ci & 5’ CJQ (Л сл r? 3 о о с -5 О сл О С/3 о о с |

|

SEALED BEARINGS seats effective seals tailed inred culler bn (beaririglessi |

|

• BC — Bir* ‘n Corta 8 Г B«< Ken TeeltvCiitters BU — Baited Up HR • CC — Clocked Cone • CD Сом* Пiegged Cl Cone tolerletence CR Corod CT Chipped Teeth Cot tars ER Erosion ГС ГЫ Crested Wear HC llnil Checking JD Junk Импорт • l С — I net Cone IN Lost Norzle |

|

BHA • Chung* Roltom Hole Assembly DMF — Downhole Mclot Failure OIF • Downhole Tool Failure DSf • Drill Slrlnq Fallure DST • Drill Stem Test DP • Drill Rug CM Condition Mud CP • Coro Porn I FM • Formation Change HP • Hole Problems I IM • I eh In Hole |

|

о Ud со |

|

ф INNER CUTTING STRUCTURE (All inner rows | OUTER CUTTING STRUCTURE (Gage row only I In columns 1 and 2 a linear scale Irom 0 to 8 Is used to describe the condition of the cutting structure according to the following STEEL TOOTH BITS. Л measure ol lost toolh tieighl due to abrasion and/or damage 0 NO LOSS OF TOOTH HEIGHT 8 TOTAL LOSS ОГ TOOTH HEIGHT. INSERT BITS A measure ol lotal culling structure reduction due lo lost, worn and’or broken inserts 0 • NO LOST. WORN AND-OR BROKEN INSERTS 4 ALL INSERT3 LOST, WORM ANO-OR BROKEN FIXED CUTTER BITS A measure oi bst. worn and/or brokenculhngstructure 0 — NO LOST, WORN AND OR BROKEN CUTTING STRUCTURE 8 ALL OF CUTTING STRUCTURE LOST. WORN ANOOR BROKEN (3) DULL CHARACTERISTICS (Use only culling sliuetiirc related codes ) |

|

LT • Lost leelh. Cull*»»* ОС • ОН С on In Woar PR — Pinched BU PN — Plugged Node Flow Passage RG — Rounded Gage RO — Ring Out SO Shirltail Oamage SS Self Sharpening Wear TR — Tracking WO Washed Out Bit WT — Worn frelh>Culler» NO No Dull Characteristic |

|

•j J |

|

ROLLER CONE |

С |

Cone |

||

|

N |

Nose Row |

CONE# |

N |

Nose |

|

M |

Middle Row |

1 |

T |

Taper |

|

G |

Gage Row |

2 |

s |

Sitoulder |

|

A |

All Rows |

3 |

G |

Gage |

|

A |

Ail Areas |

|

FIXED CUTTER |

|

BEARINGS I SEALS NON-SEALED BEARINGS A linear scale eslimaling bearing lile E used (0 No life used. 8 All Ide F used, le no bearing We remaining.! x GAGE Measure m fractiorTs of an inch I in gag* 1/16 1/16* out olgarju M 1/9* out ol gngn 1/4 1/4* o«d ol pngn |

|

® OTHER DULL CHARACTERISTIC Reler to column 3 codes © REASON PULLED OR RUN TERMINATED |

|

Hfl • Hours On Bit LOG • Run logs PP • Pump Pressure PR — Penetration Rale RIG Rig Repair TD Total Depth Casing Depth TW • Twist Off TQ • Torque WC Weather Conditions ron anrsniwuu мговмппоцсоимсг vcun LOCAL ticuwn HrrmStMfAlUt ONSCCUIStr UMWINWIRALUSblllM innuiail____________________ |

|

® LOCATION |

|

o«oi n coot ssno пм |

STEEL TOOTH BITS : a measure of the lost tooth height.

0 — Indicates no loss of tooth height due to wear or breakage 8 — indicates total loss of tooth height due to wear or breakage

INSERT BITS : a measure of total cutting structure reduction due to lost, worn and/or broken inserts

0 — Indicates no lost, worn and/or broken inserts

8 — Indicates total loss of cutting structure due to lost, worn and/or broken inserts

FIXED CUTTER : a measure of the cutting structure wear (Figure 25)

0 — Indicates no loss of cutter or diamond height due to wear or breakage 8 — Indicates total loss of cutter or diamond height due to wear or breakage

Column 3 — Cutting Structure Dull Characteristics (D)

Report the major dull characteristics of the bit cutting structure based on the table shown in Figure 24

Column 4 — Cutting Structure Location (L)

Report the location on the face of the bit where the major cutting structure dulling characteristic occurs. This may be reported in the form of a letter or number code as shown in Figure 24. The location of dull characteristics for four fixed bit profiles is shown in Figure 25.

Column 5 — Bearing Condition (B)

Report the bearing condition of roller cone bits. The grading will depend on the type of bit. This space will always be occupied by an ‘X’ for fixed cutter bits.

NON — SEALED BEARING BITS : a linear scale from 0-8 to indicate the amount of bearing life that has been used :

0 — Indicates that no bearing life has been used ( new bearing )

8 — Indicates that all of the bearing life has been used ( locked or lost )

SEALED BEARING BITS : a letter scale to indicate the condition of the seal :

E — Indicates an effective seal F — Indicates a failed seal

Column 6 — Gauge (G) :

Report on the gauge of the bit. The letter “I” is used if the bit has no gauge reduction. If the bit has gauge reduction it is reported in 1/16 ths of an inch.

Column 7 — Remarks (O) :

Report any dulling characteristic of the bit in addition to that reported for the cutting structure in column 3. Note that this is not restricted to only the cutting structure dull characteristic. The two letter codes to be used in this column are shown in Figure 24.

Column 8 — Reason for Pulling (R) :

Report the reason for pulling the bit out of the hole. This may be a two or three letter code as shown in Figure 24.

|

|