Rotary Speed

Rotary Speed

The ROP will also be affected by the rotary speed of the bit and an optimum speed must be determined. The RPM influences the ROP because the teeth must have time to penetrate and sweep the cuttings into the hole. Figure 28 shows how ROP varies with RPM for different formations. The non-linearity in hard formations is due to the time required to break down rocks of higher compressive strength. Experience plays a large part in selecting the correct rotary speed in any given situation.

The RPM applied to a bit will be a function of :

a. Type of bit

In general lower RPMs are used for insert bits than for milled tooth bits. This is to allow the inserts more time to penetrate the formation. The insert crushes a wedge of rock and then forms a crack which loosens the fragment of rock.

b. Type of formation

Harder formations are less easily penetrated and so require low RPM. A high RPM may cause damage to the bit or the drill string.

|

|

|

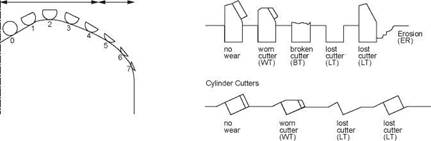

Schematic of Cutter Wear |

|

Schematic of Common Dull Characteristics |

|

Inner Area 2/3 Radius |

|

Outer Area 1/3 Radius |

|

Post or Stud Cutters |

|

Fixed Cutter Bit Profiles

Figure 25 Location of dull characteristics |

|

|

|

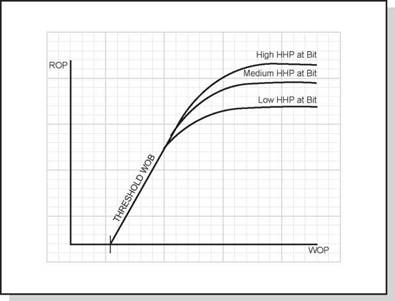

Figure 27 Penetration rate variation due to hole cleaning |

In order to prevent an influx of formation fluids into the wellbore the hydrostatic mud pressure must be slightly greater than the formation (pore) pressure. This overbalance, or positive pressure differential, forces the liquid portion of the mud (filtrate) into the formation, leaving the solids to form a filter cake on the wall of the borehole. In porous formations this filter cake prevents any further entry of mud into the formation. This overbalance and filter cake also exists at the bottom of the hole where it affects the removal of cuttings. When a tooth penetrates the surface

|

|

of the rock the compressive strength of the rock is exceeded and cracks develop, which loosen small fragments or chips from the formation (Figure 30). Between successive teeth the filter cake covers up the cracks and prevents mud pressure being exerted below the chip. The differential pressure on the chip tends to keep the chip against the formation. This is known as the static chip hold down effect, and leads to lower penetration rates. The amount of plastering which occurs depends on mud properties. To reduce the hold down effect:

• Reduce the positive differential pressure by lowering the mud weight (i. e. reduce the overbalance to the minimum acceptable level to prevent a kick).

• Reduce the solids content of the mud (both clay and drilled solids). Solids removal is essential to increase drilling efficiency.

In less porous formations the effect is not so significant since the filter cake is much thinner. However dynamic chip hold down may occur (Figure 30). This occurs because, when cracks form around the chip mud enters the cracks to equalise the pressure. In doing so, however, a pressure drop is created which tends to fix the chip against the bottom of the hole. The longer the tooth penetration, the greater the hold down pressure. Both static and dynamic hold down effects cause bit balling and bottom hole balling. This can be prevented by ensuring correct mud properties (e. g. mud weight and solids content).

PDC bits tend to drill faster with low WOB and high RPM. They are also found to require higher torque than roller cone bits. The general recommendation is that the highest RPM that can be achieved should be used. Although the torque is fairly constant in shale sections the bit will tend to dig in and torque up in sandy sections. When drilling in these sandy sections, or when the bit drills into hard sections and penetration rate drops, the WOB should be reduced but should be maintained to produce a rotary torque at least equal to that of a roller cone bit. Too low a WOB will cause premature cutter wear, possible diamond chipping and a slow rate of penetration.

The best ROP results have been achieved with oil based muds but a good deal of success has been achieved with water based muds. Reasons for the improved performance in oil based muds has been attributed to increased lubricity, decreased cutter wear temperature and preferential oil wetting of the bit body. The performance of PDC bits in respect to other mud properties is consistent with that found with roller cone bits i. e. increase in mud solids content or mudweight decreases ROP