Secondary control

Secondary control

If a kick is detected and a pit gain has occurred on surface, it is clear that primary control over the well has been lost and all normal drilling or tripping operations must cease in order to concentrate on bringing the well back under primary control.

The first step to take when primary control has been lost is to close the BOP valves, and seal off the drillstring to wellhead annulus at the surface. this is known as initiating secondary control over the well. It is not necessary to close off valves inside the drillpipe since the drillpipe is connected to the mudpumps and therefore the pressure on the drillpipe can be controlled.

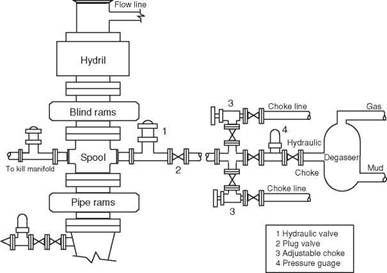

usually it is only necessary to close the uppermost annular preventer — the Hydril, but the lower pipe rams can also be used as a back up if required (Figure 7). When the well is shut in, the choke should be fully open and then closed slowly so as to prevent sudden pressure surges. the surface pressure on the drillpipe and the annulus should then be monitored carefully. these pressures can be used to identify the nature of the influx and calculate the mud weight required to kill the well.

the following procedures should be undertaken when a kick is detected. this procedure refers to fixed drilling rigs (land rigs, jack ups, rigs on fixed platforms). Special procedures for floating rigs will be given later.

For a kick detected while drilling:

(i) Raise kelly above the rotary table until a tool joint appears

(ii) Stop the mud pumps

(iii) close the annular preventer

(iv) Read shut in drill pipe pressure, annulus pressure and pit gain.

%

Before closing in the annular preventer the choke line must be opened to prevent surging effects on the openhole formations (water hammer). The choke is then slowly closed when the annular preventer is closed. Once the well is closed in it may take some time for the drill pipe pressure to stabilise, depending on formation permeability.

When a kick is detected while tripping:

(i) Set the top tool joint on slips

(ii) Install a safety valve (open) on top of the string

(iii) Close the safety valve and the annular preventer

(iv) Make up the kelly

(v) open the safety valve

(vi) Read the shut in pressures and the pit gain (increase in volume of mud in the mud pits).

The time taken from detecting the kick to shutting in the well should be about 2 minutes. Regular kick drills should be carried out to improve the rig crew’s reaction time.

|

Figure 8 BOP stack and choke manifold |