SURFACE SYSTEM

SURFACE SYSTEM

All MWD systems have a pressure transducer connected to the standpipe manifold. This transducer must be sensitive enough to detect small pressure changes (50-100 psi) occurring for only ±/< sec. The series of pulses must then be decoded and processed to give the required information.

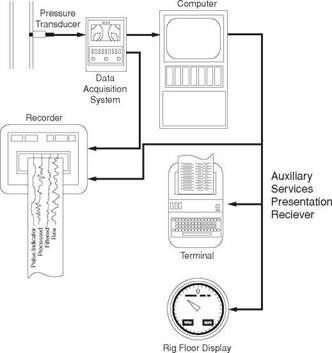

The simplest surface system is that used by Teleco (positive pulse). This has a microprocessor included in the downhole tool so that only numerical values of azimuth inclination and toolface need be transmitted to surface. A simple binary code is used whereby a pulse detected within a certain time period = 1, no pulse detected = 0. The binary number is then converted to a decimal number for the final result. The equipment necessary to do this can easily be installed in the driller’s dog house. In other systems only the raw data is sent to surface, in which case more sophisticated equipment is needed (electronic filters, computers, etc.). This equipment is usually housed in a special cabin or in the mudlogging unit. Since this cabin may be located some distance away, the survey results are relayed to a rig floor display unit where the directional driller can see them (Figure 7). Formation evaluation logs require plotting facilities which are also housed in the cabin.

|

Standpipe

Figure 7 Surface Processing and Reporting System |