THE DRILLING PROCESS

THE DRILLING PROCESS

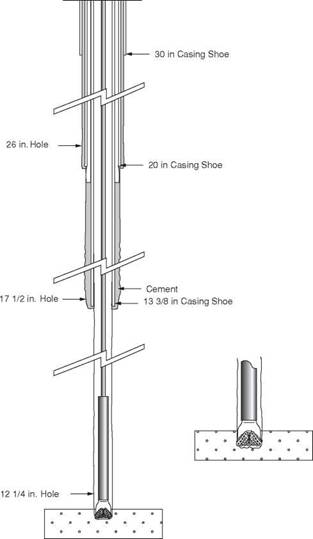

The operations involved in drilling a well can be best illustrated by considering the sequence of events involved in drilling the well shown in Figure 4. The dimensions (depths and diameters) used in this example are typical of those found in the North Sea but could be different in other parts of the world. For simplicity the process of drilling a land well will be considered below. The process of drilling a subsea well will be considered in a later chapter.

The following description is only an overview of the process of drilling a well (the construction process). The design of the well, selection of equipment and operations involved in each step will be dealt with in greater depth in subsequent chapters of this manual.

|

Figure 4 Typical hole and casing sizes |

Installing the 30” Conductor:

The first stage in the operation is to drive a large diameter pipe to a depth of approximately 100ft below ground level using a truck mounted pile-driver. This pipe (usually called casing or, in the case of the first pipe installed, the conductor ) is installed to prevent the unconsolidated surface formations from collapsing whilst drilling deeper. Once this conductor, which typically has an outside diameter (O. D.) of 30” is in place the full sized drilling rig is brought onto the site and set up over the conductor, and preparations are made for the next stage of the operation.