The "One circulation Method" ("balanced mud density" or "wait and weight" method)

The "One circulation Method" ("balanced mud density" or "wait and weight" method)

The procedure used in this method is to circulate out the influx and circulate in the heavier mud simultaneously. The influx is circulated out by pumping kill mud down the drillstring displacing the influx up the annulus. The kill mud is pumped into the drillstring at a constant pump rate and the pressure on the annulus is controlled on the choke so that the bottomhole pressure does not fall, allowing a further influx to occur.

The advantages of this method are:

• Since heavy mud will usually enter the annulus before the influx reaches surface the annulus pressure will be kept low. Thus there is less risk of fracturing the formation at the casing shoe.

• The maximum annulus pressure will only be exerted on the wellhead for a short time

• It is easier to maintain a constant Pbh by adjusting the choke.

b. Driller’s Method (Two Circulation Method)

In this method the influx is first of all removed with the original mud. Then the well is displaced to heavier mud during a second circulation.

the one circulation method is generally considered better than the Drillers method since it is safer, simpler and quicker. Its main disadvantage is the time taken to mix the heavier mud, which may allow a gas bubble to migrate.

1.7 One Circulation Well Killing Method

When an influx has been detected the well must be shut in immediately. After the pressures have stabilised, the drillpipe pressure (Pdp) and the annulus pressure (Pann) should be recorded. The required mud weight can then be calculated using Equation 7.

These calculations can be conducted while the heavy, kill mud is being mixed. these are best done in the form of a worksheet (Figure 12). It is good practice to have a standard worksheet available in the event of such an emergency. certain information should already be recorded (capacity of pipe, existing mud weight, pump output).

|

|

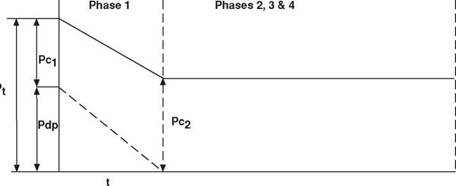

Notice on the worksheet that a slow pump rate is required. The higher the pump rate the higher the pressure drop, in the drillstring and annulus, due to friction. A low pump rate should, therefore, be used to minimise the risk of fracturing the formation. (A kill rate of 1-4 bbls/min. is recommended). the pressure drop (Pc1) which occurs while pumping at the kill rate will be known from pump rate tests which are conducted at regular intervals during the drilling operation. It is assumed that this pressure drop applies only to the drillstring and does not include the annulus. Initially, the pressure at the top of the drillstring, known as the standpipe pressure will be the sum of Pdp + Pc1 (Figure 15). the phrase standpipe pressure comes from the fact that the pressure gauge which is used to measure the pressure on the drillstring is connected to the standpipe. As the heavy mud is pumped down the drillstring, the standpipe pressure will change due to:

• Larger hydrostatic pressure from the heavy mud

• changing circulating pressure drop due to the heavy mud

By the time the heavy mud reaches the bit the initial shut-in pressure Pdp should be reduced to zero psi. The standpipe pressure should then be equal to the pressure drop due to circulating the heavier mud

i. e p _ p x _Pk

Pc2_ Pc1 X pk rn

where,

pk = kill mud gradient pm = original mud gradient

the time taken (or strokes pumped) for the drillstring volume to be displaced to heavy mud can be calculated by dividing the volumetric capacity of the drillstring by the pump output. this information is plotted on a graph of standpipe pressure vs. time or number of pump strokes (volume pumped). This determines the profile of how the standpipe pressure varies with time and number of pump strokes, during the kill procedure.

the one circulation method can be divided into 4 stages and these will be discussed separately. When circulating the influx out there will be a pressure drop across the choke, Pchoke. the pressure drop through the choke plus the hydrostatic head in the annulus should be equal to the formation pressure, Pf. thus Pchoke is equivalent to Pann when circulating through a choke.

Phase I (displacing drillstring to kill mud)

As the kill mud is pumped at a constant rate down the drillstring the choke is opened. the choke should be adjusted to keep the standpipe pressure decreasing according to the pressure vs. time plot discussed above. In fact the pressure is reduced in steps by maintaining the standpipe pressure constant for a period of time and opening the choke to allow the pressure to drop in regular increments. once the heavy mud completely fills the drillstring the standpipe pressure should become equal to Pc2. the pressure on the annulus usually increases during phase I due to the reduction in hydrostatic pressure caused by gas expansion in the annulus.

%

|

X |

Phase II (pumping heavy mud into the annulus until influx reaches the choke)

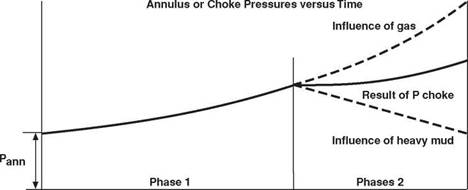

During this stage of the operation the choke is adjusted to keep the standpipe pressure constant (i. e. standpipe pressure = Pc2). the annulus pressure will vary more significantly than in phase I due to two effects:

• the increased hydrostatic pressure due to the heavy mud entering the annulus will tend to reduce Pann.

• If the influx is gas, the expansion of the gas will tend to increase Pann since some of the annular colom of mud is being replaced by gas, leading to a

decrease in hydrostatic pressure in the annulus.

The profile of annulus pressure during phase II therefore depends on the nature of the influx (Figure 16).

|

Figure 16 Effect of different kick fluids on annulus pressure |

Phase III (all the influx removed from the annulus)

As the influx is allowed to escape, the hydrostatic pressure in the annulus will increase due to more heavy mud being pumped through the bit to replace the influx. therefore, Pann will reduce significantly. If the influx is gas this reduction may be very severe and cause vibrations which may damage the surface equipment (choke lines and choke manifold should be well secured). As in phase II the standpipe pressure should remain constant.

Phase IV (stage between all the influx being expelled and heavy mud reaching surface)

During this phase all the original mud is circulated out of the annulus and is the annulus is completely full of heavy mud. If the mudweight has been calculated correctly, the annulus pressure will be equal to 0 (zero), and the choke should be fully open. The standpipe pressure should be equal to Pc2. to check that the well is finally dead the pumps can be stopped and the choke closed. The pressures on the drillpipe and the annulus should be 0 (zero). If the pressures are not zero continue circulating the heavy weight mud. When the well is dead, open the annular preventer, circulate, and condition the mud prior to resuming normal operations.