Well control system

Well control system

The function of the well control system is to prevent the uncontrolled flow of formation fluids from the wellbore. When the drillbit enters a permeable formation the pressure in the pore space of the formation may be greater than the hydrostatic pressure exerted by the mud colom. If this is so, formation fluids will enter the wellbore and start displacing mud from the hole. Any influx of formation fluids (oil, gas or water) in the borehole is known as a kick.

The well control system is designed to:

• Detect a kick

• Close-in the well at surface

• Remove the formation fluid which has flowed into the well

• Make the well safe

Failure to do this results in the uncontrolled flow of fluids — known as a blow-out — which may cause loss of lives and equipment, damage to the environment and the loss of oil or gas reserves. Primary well control is achieved by ensuring that the hydrostatic mud pressure is sufficient to overcome formation pressure. Hydrostatic pressure is calculated from:

P = 0.052 x MW x TVD

where:

P = hydrostatic pressure (psi)

MW = mud weight (ppg)

TVD = vertical height of mud column (ft)

|

|

Primary control will only be maintained by ensuring that the mud weight is kept at the prescribed value, and keeping the hole filled with mud. Secondary well control is achieved by using valves to prevent the flow of fluid from the well until such time as the well can be made safe.

There are many signs that a driller will become aware of when a kick has taken place. The first sign that an kick has taken place could be a sudden increase in the level of mud in the pits. Another sign may be mud flowing out of the well even when the pumps are shut down (i. e. without circulating). Mechanical devices such as pit level indicators or mud flowmeters which trigger off alarms to alert the rig crew that an influx has taken place are placed on all rigs. Regular pit drills are carried out to ensure that the driller and the rig crew can react quickly in the event of a kick.

Blow out preventors (BOPs) must be installed to cope with any kicks that may occur. BOPs are basically high pressure valves which seal off the top of the well. On land rigs or fixed platforms the BOP stack is located directly beneath the rig floor. On floating rigs the BOP stack is installed on the sea bed. In either case the valves are hydraulically operated from the rig floor.

There are two basic types of BOP.

|

|

|

Wear Plate |

|

Packing Unit |

|

Opening Chamber Head |

|

Lifting Shackles |

|

Opening Chamber |

|

Closing Chamber |

|

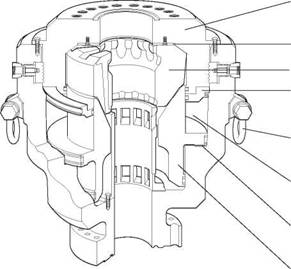

Figure 14 Hydril annular BOP (Courtesy of Hydril*) |

|

Contractor Piston |

|

Latched Head |

Annular preventor — designed to seal off the annulus between the drillstring and the side of hole (may also seal off open hole if kick occurs while the pipe is out of the hole). These are made of synthetic rubber which, when expanded, will seal off the cavity (Figure 14).

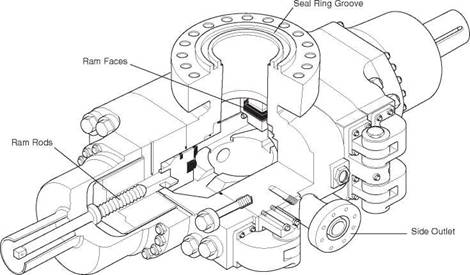

Ram type preventor — designed to seal off the annulus by ramming large rubberfaced blocks of steel together. Different types are available:

blind rams — seal off in open hole

pipe rams — seal off around drillpipe (Figure 15)

shear rams — sever drillpipe (used as last resort)

|

Figure 15 Ram type BOP (Courtesy of Hydril*) |

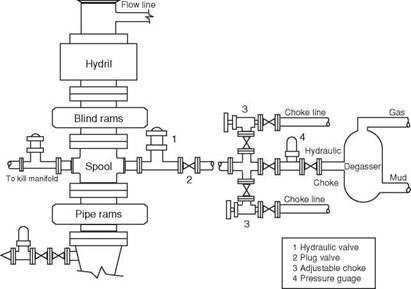

Normally the BOP stack will contain both annular and ram type preventors ( Figure 16).

|

Figure 16 BOP stackup Institute of Petroleum Engineering, Heriot-Watt University 25 |

To stop the flow of fluids from the drillpipe, the kelly cock valves can be closed, or an internal BOP (basically a non-return check valve preventing upward flow) can be fitted into the drillstring.

To remove the formation fluids now trapped in the annulus a high pressure circulating system is used. A choke manifold with an adjustable choke is used to control flow rates during the circulation. Basically heavier mud must be pumped down the drillpipe to control the formation pressure, and the fluids in the annulus circulated to surface. As the kick starts moving up the hole the choke opening is restricted to hold enough back pressure on the formation to prevent any further influx. The fluids are circulated out via the choke line, through the choke manifold out to a gas/mud separator and a flare stack (Figure 16). Once the heavier mud has reached surface the well should be dead. Well control procedures will be dealt with more fully later.