COLLAPSE PRESSURE

COLLAPSE PRESSURE

Primary collapse loads are generated by the hydrostatic head of the fluid column outside the casing string. These fluids are usually drilling fluids and. sometimes, cement slurry. Casing is also subjected to severe collapse pressure when drilling through troublesome formations such as: plastic clays and salts.

Strength of the casing under external pressure depends, in general, on a number of factors. Those considered most important when determining the critical collapse strength are: length, diameter, wall thickness of the casing and the physical properties of the casing material (yield point, elastic limit. Poisson’s ratio, etc.).

|

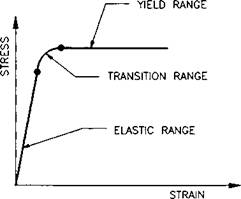

Fig. 2.8 : Elastoplastic material behavior with transition range for steel casing under collapse pressure. |

Casing specimens manufactured out of steel with elastic ideal-plastic material behavior can fail in three possible ways when subjected to overload due to external pressure: elastic, plastic, and by exceeding the ultimate tensile strength of material (Fig. 2.8).

Casing having a low d0/t ratio and low strength, reaches the critical collapse value as soon as the material begins to yield under the action of external pressure. Specimens exhibit ideally-plastic collapse behavior and the failure due to external pressure occurs in the so-called ‘yield range’.

In contrast to low d0/t and low strength failure in the yield range, casing with high da/t ratio and high strength, collapses below the yield strength of the material. The ability of these pipes to withstand external pressure is limited by the failure by collapse rather than buckling, of long, thin struts while in compression. In this case, failure is caused by purely elastic deformation of the casing and results

in out-of-roundness of the pipe. The collapse behavior is known as failure in the elastic range.

A systematic procedure for determining the different collapse strengths is given in the following sections.