Pipe Weight

Pipe Weight

According to the API Bui. 5C3 (1989). pipe weight is defined as nominal weight, plain end weight, and threaded and coupled weight. Pipe weight is usually ex-

|

Table 1.5: Example 1: makeup loss in 10,000 ft strings for different API casing lengths.

|

pressed in lb/ft. The API tolerances for weight are: +6.5% and -3.5% (API Spec. 5CT, 1992).

Nominal weight is the weight of the casing based on the theoretical weight per foot for a 20-ft length of threaded and coupled casing joint. Thus, the nominal weight, IT’„ in lb/ft, is expressed as:

IT; = 10.68 (d0 — i)t + 0.0722 d20 (1.1)

where:

VT; = nominal weight per unit length, lb/ft. d0 — outside diameter, in.

1 = wall thickness, in.

The nominal weight is not the exact weight of the pipe, but rather it is used for the purpose of identification of casing types.

The plain end weight is based on the weight of the casing joint excluding the

threads and couplings. The plain end weight. lTpf. in lb/ft. is expressed as:

TTpP = 10.68 (d0 — t) lb/ft (1.2)

Threaded and coupled weight, on the other hand, is the average weight of the

pipe joint including the threads at both ends and coupling at one end when in

the power tight position. Threaded and coupled weight. IT,… is expressed as:

IT% = — { (Wpe [20 — (Lc + 2.У)/24] + Weight of coupling

— Weight removed in threading two pipe ends } (1.3)

where:

CENTER OF

|

|

|

ZZZZ |

coupling!

COUPLING

|

|

|

|

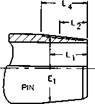

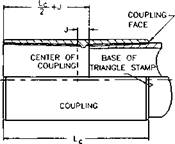

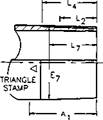

L-, PIPE END TO HAND TIGHT PLANE E] PITCH DIAMETER AT HAND TIGHT PLANE

L2 MINIMUM LENGTH, FULL CRESTED THREAD E7 PITCH DIAMETER AT L7 DISTANCE

l4 THREADED LENGTH J END OF POWER TIGHT PIN TO

CENTER OF COUPLING

l7 TOTAL LENGTH. PIN TIP TO VANISH

POINT LENGTH, PERFECT THREADS Lc LENGTH OF COUPLING

Fig. 1.6 : Basic axial dimensions of casing couplings: API Round threads (top). API Buttress threads (bottom).

IT(C = threaded and coupled weight, lb/ft.

Lc = coupling length, in.

J = distance between the end of the pipe and center of the

coupling in the power tight position, in.

The axial dimensions for both API Round and API Buttress couplings are shown in Fig. 1.6.