Balanced activity

Balanced activity

The activity of a substance is its affinity or potential for water. All rocks which contain clay will absorb water to some extent. This is because there is a difference between the activity of the shales and the activity of the mud. If the chemical potentials of the shale and the mud were equal the shale would not absorb any water. This would eliminate any swelling of the clays, leading to borehole instability. For balanced activity in an oil-based mud the activity of the mud (Aw) must be adjusted to equal the activity of the formation being drilled. CaCl2 or NaCl may be added to the mud to keep Aw above 0.75. The activity of the shale can be measured by taking samples from the shaker.

Water

|

(Solid is preferentially water wet) |

|

w |

Solid

Case IV : Ow = 0°

(Solid is totally water wet)

|

Oil |

|

o |

|

3 |

|

Solid Case V : O = O° 0 (Solid is totally oil wet) |

|

Oil |

Water |

|

o |

o |

|

0 |

w |

|

b |

Solid |

|

Case II : |

o = O = 90° |

|

w о |

|

(Solid is non-preferential in wetting) |

|

|

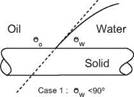

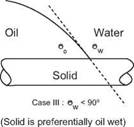

Figure 16 Contact angles in three phase systems

Excessive viscosity in an oil-based mud may be the result of:

• Too much water content — When water is properly emulsified it behaves like a solid. As the water fraction increases so does the viscosity

• Drilled solids — The solids content affects viscosity in oil-based in the same way as water-based muds. The build up of fine solids (e. g. due to diamond bit drilling) may produce high PV, YP and gel strengths. Finer shaker screens (120 mesh) should be used to reduce this effect. Water wet soldis may also cause problems with high YP

It is recommended that pilot tests should be done to assess the implications of adding chemicals to the mud to control viscosity. Emulsifiers and wetting agents may be added to reduce viscosity.

Water and special viscosifiers (organically treated bentonite) may be added to the mud to increase viscosity.

Only the oil phase in OBM is free to form a filtrate, making an oil-based mud suitable for formations which must not be damaged. The fluid loss is generally very small with oil-based muds (<3cc at 500 psi and 300 degrees F). During the test there should never be water present in the filtrate (indicates a poor emulsion). If water is present more emulsifying agent should be added. Excessive filtrate volumes can be cured by adding polymers, lignite etc. (pilot tests are recommended).