Cementing

Cementing

LEARNiNG OBJECTiVES :

Having worked through this chapter the student will be able to:

General

• Describe the principal functions of cement.

Cement Slurries

List and describe the major properties of a cement slurry.

Describe the additives used in cement slurries and the way in which they affect the properties of the slurry.

Cementing Operations

Calculate the volume of : slurry, cement, mixwater, displacing fluid required for a single stage and two-stage cementing operation.

Calculate the bottomhole pressures generated during the above cementing operations.

Describe the surface and downhole equipment used in a single, two-stage and liner cementation operation.

Prepare a program for a single and two stage cementing operation and describe the ways in which a good cement bond can be achieved.

Cement Plugs

Describe the reasons for setting cement plugs.

Describe the principal methods for placing a cement plug in casing or open hole.

Calculate the displacement volumes for an underbalanced cement plug.

Evaluation of Cementing Operations

Describe the principles involved and the tools and techniques used to evaluate the quality of a cementing operation.

Discuss the limitations of the above techniques.

Cement is used primarily as an impermeable seal material in oil and gas well drilling. It is most widely used as a seal between casing and the borehole, bonding the casing to the formation and providing a barrier to the flow of fluids from, or into, the formations behind the casing and from, and into, the subsequent hole section (Figure 1). Cement is also used for remedial or repair work on producing wells. It is used for instance to seal off perforated casing when a producing zone starts to produce large amounts of water and/or to repair casing leaks. This chapter will present: the reasons for using cement in oil and gas well drilling; the design of the cement slurry; and the operations involved in the placement of the cement slurry. The methods used to determine if the cementing operation has been successful will also be discussed.

1.1 Functions of oilwell cement

There are many reasons for using cement in oil and gaswell operations. As stated above, cement is most widely used as a seal between casing and the borehole, bonding the casing to the formation and providing a barrier to the flow of fluids from, or into, the formations behind the casing and from, and into, the subsequent hole section (Figure 1). However, when placed between the casing and borehole the cement may be required to perform some other tasks. The most important functions of a cement sheath between the casing and borehole are:

• To prevent the movement of fluids from one formation to another or from the formations to surface through the annulus between the casing and borehole.

• To support the casing string (specifically surface casing)

• To protect the casing from corrosive fluids in the formations.

However, the prevention of fluid migration is by far the most important function of the cement sheath between the casing and borehole. Cement is only required

to support the casing in the case of the surface casing where the axial loads on

the casing, due to the weight of the wellhead and BOP connected to the top of the casing string, are extremely high. The cement sheath in this case prevents the casing from buckling.

The techniques used to place the cement in the annular space will be discussed in detail later but basically the method of doing this is to pump cement down the inside of the casing and through the casing shoe into the annulus (Figure 2). This operation is known as a primary cement job. A successful primary cement job is essential to allow further drilling and production operations to proceed.

|

|

|

Normally pressured |

Abnormally pressured

Figure 1 Functions of Primary Cementing

|

Circulating mud |

|

Pumping spacer and slurry |

|

Displacing |

|

Displacing |

|

End of job

|

|

O Plug release pin out |

|

|

|

|

|

|

|

|

|

Apply squeeze pressure |

|

ш |

|

|

|

Spot cement |

Schematic of Bradenhead squeeze technique normally used on low pressure formations. Cement is circulated into place down drill pipe (left), then the wellhead, or BOP, is closed (centre) and squeeze pressure is applied. Reverse circulating through perforations (right) removes excess cement, or the plug can be drilled out.

Figure 3 Secondary or Squeeze Cementing Operation

Another type of cement job that is performed in oil and gas well operations is called a secondary or squeeze cement job. This type of cement job may have to be done at a later stage in the life of the well. A secondary cement job may be performed for many reasons, but is usually carried out on wells which have been producing for some time. They are generally part of remedial work on the well (e. g. sealing off water producing zones or repairing casing leaks). These cement jobs are often called squeeze cement jobs because they involve cement being forced through holes or perforations in the casing into the annulus and/or the formation (Figure 3).

The specific properties of the cement slurry which is used in the primary and secondary cementing operations discussed above will depend on the particular reason for using the cement (e. g. to plug off the entire wellbore or simply to plug off perforations) and the conditions under which it will be used (e. g. the pressure and temperature at the bottom of the well).

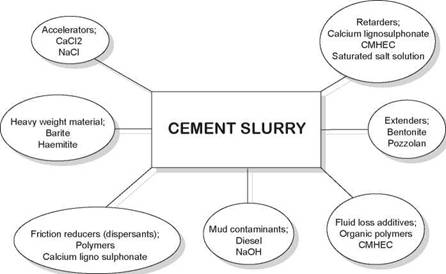

The cement slurry which is used in the above operations is made up from: cement powder; water; and chemical additives. There are many different grades of cement powder manufactured and each has particular attributes which make it suitable for a particular type of operation. These grades of cement powder will be discussed below. The water used may be fresh or salt water. The chemical additives (Figure

|

Figure 4 Major cement additives |

|

API Class |

1 C3S |

C2S |

C3A |

C4AF |

CaSO4 1 |

SQq. cm/Gram |

|

A |

53 |

24 |

8 |

8 |

3.5 |

1600-1900 |

|

B |

44 |

32 |

5 |

12 |

2.9 |

1500-1900 |

|

C |

58 |

16 |

8 |

8 |

4.1 |

2000-2400 |

|

D&E |

50 |

26 |

5 |

13 |

3 |

1200-1500 |

|

G |

52 |

27 |

3 |

12 |

3.2 |

1400-1600 |

|

H |

52 |

25 |

5 |

12 |

3.3 |

1400-1600 |

|

Compounds* |

|

Fineness |

|

*Plus free lime, alkali, (Na, K, Mg) |

|

Table 1 Composition of API Cements |

|

% |

|

4) which are mixed into the cement slurry alter the properties of both the cement slurry and the hardened cement and will be discussed at length in Section 3 below. |

Each cement job must be carefully planned to ensure that the correct cement and additives are being used, and that a suitable placement technique is being employed for that particular application. In planning the cement job the engineer must ensure that:

• The cement can be placed correctly using the equipment available

• The cement will achieve adequate compressive strength soon after it is placed

• The cement will thereafter isolate zones and support the casing throughout the life of the well

To assist the engineer in designing the cement slurry, the cement slurry is tested in the laboratory under the conditions to which it will be exposed in he wellbore. Theses tests are known as pilot tests and are carried out before the job goes ahead. These tests must simulate downhole conditions as closely as possible. They will

help to assess the effect of different amounts of additives on the properties of the cement (e. g. thickening time, compressive strength development etc).

|

API Class |

Mixwater |

Slurry Weight |

|

Gals/Sk. |

Lbs/Gal. |

|

|

A |

5.2 |

15.6 |

|

B |

5.2 |

15.6 |

|

C |

6.3 |

14.8 |

|

D |

4.3 |

16.4 |

|

E |

4.3 |

16.4 |

|

F |

4.3 |

16.2 |

|

G |

5.0 |

15.8 |

|

H |

4.3 |

16.4 |

|

Table 2 API Mixwater requirements for API cements 1.2 Classification of cement powders There are several classes of cement powder which are approved for oilwell drilling applications, by the American Petroleum Institute — API. Each of these cement powders have different properties when mixed with water. The difference in properties produced by the cement powders is caused by the differences in the distribution of the four basic compounds which are used to make cement powder; C3S, C2S, C3A, C4AF (Table 1). |

Classes A and B — These cements are generally cheaper than other classes of cement and can only be used at shallow depths, where there are no special requirements. Class B has a higher resistance to sulphate than Class A.

Class C — This cement has a high C3S content and therefore becomes hard relatively quickly.

Classes D, E and F — These are known as retarded cements since they take a much longer time to set hard than the other classes of cement powder. This retardation is due to a coarser grind. These cement powders are however more expensive than the other classes of cement and their increased cost must be justified by their ability to work satisfactorily in deep wells at higher temperatures and pressures.

Class G and H — These are general purpose cement powders which are compatible with most additives and can be used over a wide range of temperature and pressure. Class G is the most common type of cement and is used in most areas. Class H has a coarser grind than Class G and gives better retarding properties in deeper wells.

There are other, non-API, terms used to classify cement. These include the following:

• Pozmix cement — This is formed by mixing Portland cement with pozzolan (ground volcanic ash) and 2% bentonite. This is a very lightweight but durable cement. Pozmix cement is less expensive than most other types of cement and due to its light weight is often used for shallow well casing cementation operations.

%

|

Portland |

API Class G |

API ClassH |

|||

|

Water, |

5.19 |

4.97 |

4.29 |

||

|

gal./sk. |

|||||

|

Slurry Wt. |

15.9 |

15.8 |

16.5 |

||

|

lb./gal. |

|||||

|

Slurry Vol. |

1.8 |

1.14 |

1.05 |

||

|

cuft./sk. |

|||||

|

Temp. (deg. F) Pressure (psi) |

Typical comp. strength (psi) @ 12hrs |

||||

|

60 |

0 |

615 |

440 |

325 |

|

|

80 |

0 |

1470 |

1185 |

1065 |

|

|

95 |

800 |

2085 |

2540 |

2110 |

|

|

110 |

1600 |

2925 |

2915 |

2525 |

|

|

140 |

3000 |

5050 |

4200 |

3160 |

|

|

170 |

3000 |

5920 |

4380 |

4485 |

|

|

200 |

3000 |

— |

5110 |

4575 |

|

|

Typical comp. strength (psi) @ 24hrs |

|||||

|

60 |

0 |

2870 |

— |

— |

|

|

80 |

0 |

4130 |

— |

— |

|

|

95 |

800 |

4130 |

— |

— |

|

|

110 |

1600 |

5840 |

— |

— |

|

|

140 |

3000 |

6550 |

— |

7125 |

|

|

170 |

3000 |

6210 |

5865 |

7310 |

|

|

200 |

3000 |

7360 |

9900 |

||

|

Table 3 Compressive strength of cements |

• Gypsum Cement — This type of cement is formed by mixing Portland cement with gypsum. These cements develop a high early strength and can be used for remedial work. They expand on setting and deteriorate in the presence of water and are therefore useful for sealing off lost circulation zones.

• Diesel oil cement — This is a mixture of one of the basic cement classes (A, B, G, H ), diesel oil or kerosene and a surfactant. These cements have unlimited setting times and will only set in the presence of water. Consequently they are often used to seal off water producing zones, where they absorb and set to form a dense hard cement.

The water which is used to make up the cement slurry is known as the mixwater. The amount of mixwater used to make up the cement slurry is shown in Table 2. These amounts are based on :

• The need to have a slurry that is easily pumped.

• The need to hydrate all of the cement powder so that a high quality hardened cement is produced.

• The need to ensure that all of the free water is used to hydrate the cement powder and that no free water is present in the hardened cement.

The amount of mixwater that is used to make up the cement slurry is carefully controlled. If too much mixwater is used the cement will not set into a strong, impermeable cement barrier. If not enough mixwater is used :

• The slurry density and viscosity will increase.

• The pumpability will decrease

• Less volume of slurry will be obtained from each sack of cement

The quantities of mixwater quoted in Table 2 are average values for the different classes of cement. Sometimes the amount of mixwater used will be changed to meet the specific temperature and pressure conditions which will be experienced during the cement job.