Cutting Structure

Cutting Structure

The teeth of a milled tooth bit and the inserts of an insert bit for the cutting structure of the bit. The selection of a milled tooth or insert bit is largely based on the hardness of the formation to be drilled. The design of the cutting structure will therefore be based on the hardness of the formation for which it will be used. The main considerations in the design of the cutting structure is the height and spacing of teeth or inserts.

|

|

Soft formation bits require deep penetration into the rock so the teeth are long, thin and widely spaced to prevent bit balling. Bit balling occurs when soft formations are drilled and the soft material accumulates on the surface of the bit preventing the teeth from penetrating the rock. The long teeth take up space, so the bearing size must be reduced. This is acceptable since the loading should not be excessive in soft formations.

Moderately hard formation bits are required to withstand heavier loads so tooth height is decreased, and tooth width increased. Such bits rely on scraping/gouging action with only limited penetration. The spacing of teeth must still be sufficient to allow good cleaning.

Hard formation bits rely on a chipping action and not on tooth penetration to drill, so the teeth are short and stubbier than those used for softer formations. The teeth must be strong enough to withstand the crushing/chipping action and sufficient numbers of teeth should be used to reduce the unit load. Spacing of teeth is less critical since ROP is reduced and the cuttings tend to be smaller.

The cutting structure for insert bits follows the same pattern as for milled tooth bits. Long chisel shaped inserts are required for soft formations, while short ovide shaped inserts are used in hard formation bits.

Tungsten carbide hardfacing is applied to the teeth of soft formation bits to increase resistance to the scraping and gouging action. Hard formation bits have little or no hardfacing on the teeth, but hardfacing is applied to the outer surface (gauge) of the bit. If the outer edge of the cutting structure is not protected by tungsten carbide hardfacing two problems may occur.

|

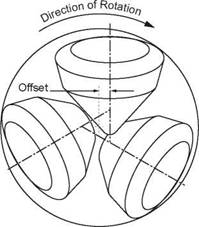

Figure 11 Offset in soft formation bits |

• The outer surface of the bit will be eroded by the abrasive formation so that the hole diameter will decrease. This undergauge section of the hole will have to be reamed out by the next bit, thus wasting valuable drilling time

• If the gauge area is worn away it causes a redistribution of thrust forces throughout the bearing assembly, leading to possible bit failure and leaving junk in the hole (e. g. lost cones)