Downhole System

Downhole System

The downhole system consists of:

• The Non-Rotating Steerable Stabiliser;

• The electronics probe and

• The Reservoir navigation or MWD Tool.

Non-Rotating Steerable Stabilizer

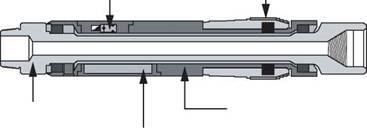

The Steering Unit contained within a non-rotating sleeve controls the direction of the bit. A drive shaft rotates the bit through the non-rotating sleeve. The sleeve is decoupled from the drive shaft and is therefore not affected by drillstring rotation. This sleeve contains three hydraulically operated ribs, the near bit inclinometer and control electronics. Pistons — operated by high pressure hydraulic fluid — exert controlled forces separately to each of the three steering ribs. The system applies a different, controlled hydraulic force to each steering rib and the resulting force vector directs the tool along the desired trajectory at a programmed dogleg severity. This force vector is adjusted by a combination of downhole electronic control and commands pulsed hydraulically from the surface.

|

Hydraulic Control Valves Steering Ribs

Rotating Shaft Drive Control Electronics and Inclination Sensors Non-Rotating Steerable Stabilizer Sleeve |

|

□ |

Figure 11 Non-Rotating Steerable Stabilizer (Courtesy of Baker Hughes Inteq.)

The micro-processing system inside the AutoTrak RCLS calculates how much pressure has to be applied to each piston to obtain the desired toolface orientation. In determining the magnitude of the force applied to the steering ribs, the system also takes into account the dogleg limits for the current hole selection.

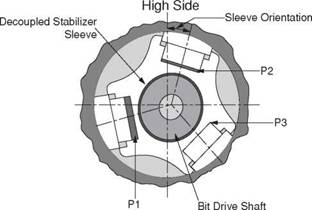

In field tests, the sleeve has been seen to rotate at approximately one revolution every W hour, depending on both the formation type and ROP. To compensate, the system continuously monitors the relative position of the sleeve. Using these data, AutoTrak RCLS automatically adjusts the force on each steering rib to provide a steady side force at the bit in the desired direction.

|

Figure 12 End section of Non-Rotating Steerable Stabilizer (Courtesy of Baker Hughes Inteq.) |

Electronics Probe

The Electronics Probe controls the interface between all tool components and manages the exchange of data to and from the surface. This section also contains directional and tool vibration sensors. Azimuth measurements from the tri-axial

A

|

% |

magnetometer monitor and control the steering unit in conjunction with the near bit inclinometer, providing early readings of tool inclination changes. The vibration sensor helps ensure that AutoTrak RCLS is operated within specifications and at maximum efficiency.

Reservoir Navigation Tool

The Reservoir Navigation Tool (RNT) sub — with Multiple Propagation Resistivity (MPR) and Dual Azimuthal Gamma Ray (GR) sensors — enables real-time geosteering within the reservoir. Using two frequencies and dual transmitters, the RNT provides four (4) compensated resistivity measurements for accurate determination of Rt under a variety of conditions. The system provides deep-reading 400 kHz measurements and high vertical resolution 2 MHz readings. While drilling horizontally, the 400 kHz readings can detect contrasting bed boundaries and fluid contacts up to 18 feet (5.5 m) from the tool. In a horizontal application, this enables drillers to anticipate boundaries more than 250 ft (75 m) ahead of the bit. These two frequency readings and Dual Azimuthal Gamma Ray measurement enable AutoTrak operators to downlink course corrections to keep the well in the zone of interest.