DRILL STRING DESIGN

DRILL STRING DESIGN

There are four basic requirements which must be met when designing a drillstring:

• The burst, collapse and tensile strength of the drillstring components must not be exceeded

• The bending stresses within the drill string must be minimised.

• The drillcollars must be able to provide all of the weight required for drilling.

• The BHA must be stabilised to control the direction of the well.

7.1. Design of a Stabilised String

|

|

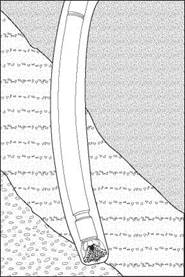

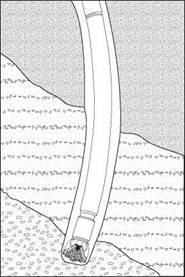

A drilling bit does not normally drill a vertical hole. This is partly due to the forces acting on the string by sloping laminar formations. When the slope (or dip) of the beds is less than 45 degrees the bit tends to drill up-dip (perpendicular to the layers). If the dip is greater than 45 degrees it tends to drill parallel to the layers (see Figure 12). In hard rock, where greater WOB is applied, the resulting compression and bending of the drillstring may cause further deviation. There are two techniques for controlling deviation.

|

|

Figure 12 Drilling through dipping strata

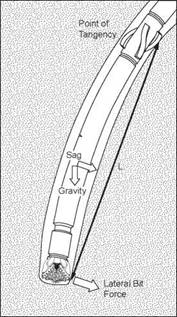

• Packed hole assembly (Figure 13) — This is basically a stiff assembly, consisting of reamers, drill collars and stabilisers. The purpose of this design is to align the bit with the hole already drilled and minimise the rate of change in deviation.

• Pendulum assembly — The first stabiliser of a pendulum assembly is placed some distance behind the bit. The unsupported section of drill collar (Figure 13) swing to the low side of the hole. A pendulum assembly will therefore tend to decrease the angle of deviation of the hole and tend to produce a vertical hole. This will tend to reduce deviation. The distance “L” from the bit up to the point of wall contact is important, since this determines the pendulum force. To increase this distance, a stabiliser can be positioned some distance above the bit. If placed too high the collars will sag against the hole and reduce the pendulum force. The optimum position for

|

if |

|

|

the stabiliser is usually based on experience, although theoretical calculations can be done. When changing the hole angle it must be done smoothly to avoid dog legs (abrupt changes in hole angle). The method of calculating dog leg severity will be given later. Some typical Bottom hole assemblies (BHA), for different drilling conditions, are given in Figure 14.

|

|

PENDULUM AssEMBLY PACKED HoLE AssEMBLY

Figure 13 Pendulum effect

the stabiliser is usually based on experience, although theoretical calculations can be done. When changing the hole angle it must be done smoothly to avoid dog legs (abrupt changes in hole angle). The method of calculating dog leg severity will be given later. Some typical Bottom hole assemblies (BHA), for different drilling conditions, are given in Figure 14.

|

V/ |