WELL CONTROL PRINCIPLES

WELL CONTROL PRINCIPLES

There are basically two ways in which fluids can be prevented from flowing, from the formation, into the borehole:

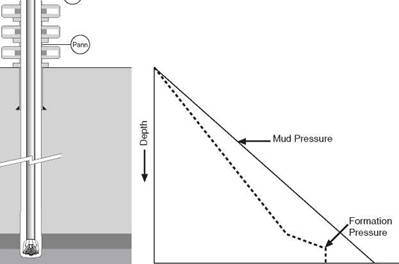

Primary control over the well is maintained by ensuring that the pressure due to the colom of mud in the borehole is greater than the pressure in the formations being drilled i. e. maintaining a positive differential pressure or overbalance on the formation pressures. (Figure 1)

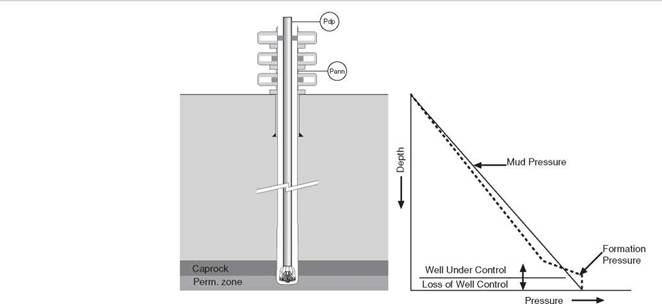

Secondary control is required when primary control has failed (e. g. an unexpectedly high pressure formation has been entered) and formation fluids are flowing into the wellbore. The aim of secondary control is to stop the flow of fluids into the wellbore and eventually allow the influx to be circulated to surface and safely discharged, while preventing further influx downhole. The first step in this process is to close the annulus space off at surface, with the BOP valves, to prevent further influx of formation fluids (Figure 2). The next step is to circulate heavy mud down the drillstring and up the annulus, to displace the influx and replace the original mud (which allowed the influx in the first place). The second step will require flow the annulus but this is done in a controlled way so that no further influx occurs at the bottom of the borehole. The heavier mud should prevent a further influx of formation fluid when drilling ahead. The well will now be back under primary control.

|

|

|

Figure 1 Primary Control — Pressure due to mud colom exceeds Pore Pressure |

|

Caprock Perm. zone |

|

Pressure |

|

Figure 2 Secondary Control — Influx Controlled by Closing BOP’s |

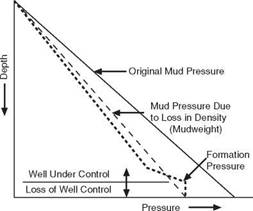

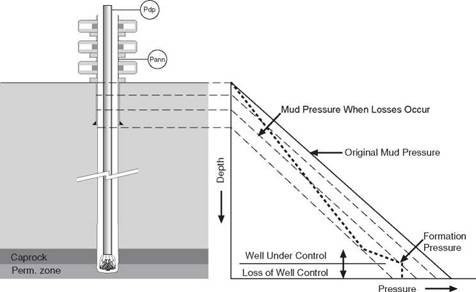

Primary control of the well may be lost (i. e. the borehole pressure becomes less than the formation pressure) in two ways. The first is if the formation pressure in a zone which is penetrated is higher than that predicted by the reservoir engineers or geologist. In this case the drilling engineer would have programmed a mud weight that was too low and therefore the bottomhole pressure would be less than the formation pressure (Figure 1). The second is if the pressure due to the colom of mud decreases for some reason, and the bottomhole pressures drops below the formation pressure. Since the bottomhole pressure is a product of the mud density and the height of the colom of mud. The pressure at the bottom of the borehole can therefore only decrease if either the mud density or the height of the colom of mud decreases (Figures 3 and 4).

There are a number of ways in which the density of the mud (mudweight) and/or the height of the colom of mud can fall during normal drilling operations.

i

—0

|

|

|

Figure 3 Loss of Primary Control — Due to Reduction in Mudweight |

|

Caprock Perm. zone |

|

Figure 4 Loss of Primary Control — Due to Reduction in fluid level in borehole |