Chapter 6 — A 1.4 MW wood gas fuelled power plant in Paraguay

Chapter 6 — A 1.4 MW wood gas fuelled power plant in Paraguay

In Loma Plata in the Chaco region of Paraguay, the German company Imbert installed-in 1983 a 1.4 MW power plant fuelled by wood-gas. Originally the plant consisted of two downdraught gasifiers, with a nominal gas-production capacity of 1800 m3/h each, but in October 1985 was-equipped with a third gasifier of local design and manufacture. The gasifiers feed three Waukesha L7042 G gas-engine-alternator sets, with a generating capacity of 420 kVA each. The power plant supplies a private agricultural cooperative of small-scale industries, bakeries, dairies, schools and some 1,500 families with electricity.

Up till now (February 1986) the first two gasifiers have been in-operation for more than two years and the third for more than three months. The power-plant has been working without major problems and enabled the cooperative to develop and improve its economy through lower energy costs, increased electricity supply and new jobs.

The-average wood-fuel consumption per produced kWh electricity has been 1.9 kg/kWh, with a fuel cost of 2.9 G/kg, compared to the cost of diesel oil, which has risen from 72 G/l in January 1984 to 127 G/l in December 1984.

In the following sections a more detailed description of the power-plant, the wood fuel preparation and the electricity production costs, as reported by Sonnenberg & al. (37) and Canete (9), are presented.

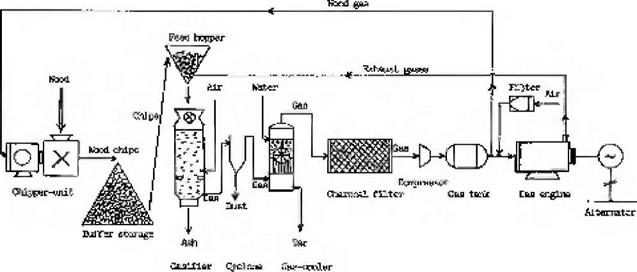

A schematic layout of the Loma Plata power plant is shown in Figure 6.1.

In 1981 the Development Department of BNF (Banco Nacional de Fomento de Paraguay) in cooperation with the technical and administrative division of the Chortitzer Cooperative Committee in the Chaco region carried out a feasibility study of establishing an electricity generating power plant using wood-gas as fuel. The study included many fuel alternatives and concluded that the use of wood-gas would be the most feasible and profitable solution for the Chaco region.

|

Figure 6.1 Flow diagram for the wood-gas fuelled power plant at Loma Plata (3 Gasifier-engine units)

|

The conclusions were based on the following facts:

1) the possibility of avoiding the use of fossil fuels for electricity generation;

2) creation of new jobs in fuelwood harvesting, transportation and preparation;

3) utilization of the forest residues unsuitable for industrial processing;

4) reducing the costs of farmers preparing new agricultural land by having the possibility to sell the cut wood as fuel;

5) the fuelwood resources of the area will cover the needs of the power plant for a long time;

6) no need of good quality cooling — or boiler water;

7) avoiding the transportation of fuel oil over long distances, with continuously growing costs;

8) considerably lower costs per produced kWh electricity with wood-gas than with diesel oil;

9) savings of foreign currency both on a national and regional level, by decreasing the need for imported oil;

10) development of regional self-sufficiency in the zone, without being dependent on climate and oil supply (the routes are often closed because of rainfall), and improvement of the economy because of smaller oil bills for the power-plant and smaller electricity bills for the industry in the zone.

Leaning on the facts of the feasibility study the Chortitzer Cooperative decided to ask for a loan, to realize the wood-gas project, with an estimated total cost of 320 million G. This would be the first power-plant of this size in South America producing electricity with a biomass-based fuel.

The first two years of operation have created great interest among representatives of the government, technical institutions and both national and foreign agents and decision makers, who have paid frequent visits to the Loma Plata power-plant.