Description of the wood gas power plant

Description of the wood gas power plant

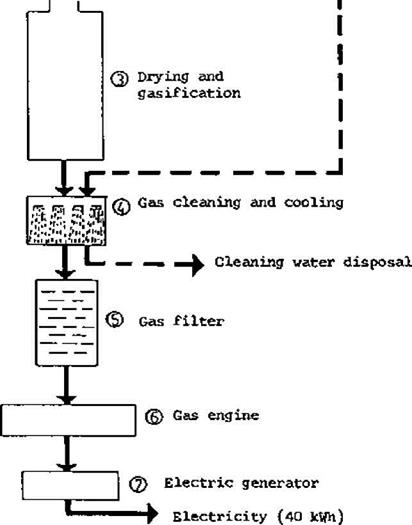

Figure 4.1 shows a schematic flow diagram for the electricity generation process. A more detailed flow diagram for the gasifier system is shown in Figure 4.2

Table 4.1 summarizes technical data for the plant.

|

Table 4.1 Technical data of downdraught wood gasifier power plant at the Sapire sawmill

|

The sawmill is located in a forest area with abundant wood. The roads in this area are unpaved so the sawmill keeps stocks in a log yard to maintain the supply of raw material during rainy periods.

The wood supply for the gasifier is completely covered since it comes from the sawmill wastes. On average, these wastes amount to 35% of the log input, a quantity exceeding the needs of the wood gasifier (about 570 t/year). There is thus no need to economize on the fuel and in fact as much as possible is used so as to reduce the area needed for storage.

Table 4.2 shows the wood species used as gasifier fuel and the bulk densities of the corresponding wood chips.

Figure 4.1 Flow diagram for the gasifier system of the power plant at the Sapire

|

|||||||||||||

|

|

Cedar |

Cedrella tissilis |

5b4 |

|

iGuaca |

lOcotea puberula |

448 |

|

Guatambu ■ |

Aspidooperma Austr. |

883 |

The maximum dimensions of the wood fuel are 40 x 40 x 5 cm, i. e. the largest that can be fed into the loading chute of the gasifier, and smaller pieces, down to the size of a matchbox, are all accepted. In theory, about ten percent of shavings and sawdust can be included, but in practice this has produced poor results because the sawmill has an earth floor and dust tends to be swept up with the wood waste.

The maximum moisture content recorded was 37 percent, decreasing with size and the length of time the logs are stored before conversion. The moisture content therefore varies with sawmill operations and the seasons.

Variations of wood moisture content below the maximum do not affect the quality of fuel gas because the feedstock dries in the bunker section of the gasifier before-it reaches the pyrolysis zone.