Means both sealed friction bearings and gauge protection included

Means both sealed friction bearings and gauge protection included

Additional Table — Additional Design Features

An additional Table is supplied with the bit classification chart. This table defines additional features of the bit. Eleven characters are used to describe features such as: extended nozzles; additional nozzles; suitability for air drilling etc.

If a bit is classified as 1-2-4-E this means that it is a soft formation, milled tooth bit with sealed roller bearings and extended nozzles.

The terms “soft” “medium” and “hard” formation are very broad categorisations of the geological strata which is being penetrated. In general the rock types within each category can be described as follows:

|

|

Soft formations are unconsolidated clays and sands. These can be drilled with a relatively low WOB (between 3000-5000 lbs/in of bit diameter) and high RPM (125-250 RPM). Large flow rates should be used to clean the hole effectively since the ROP is expected to be high. Excessive flow rates however may cause washouts. Flow rates of 500-800 gpm are recommended. As with all bit types, local experience plays a large part in deciding the operating parameters.

• Medium formations may include shales, gypsum, shaley lime, sand and siltstone. Generally a low WOB is sufficient (3000-6000 lbs/in of bit diameter). High rotary speeds can be used in shales but chalk requires a slower rate (100-150 RPM). Soft sandstones can also be drilled within these parameters. Again high flow-rates are recommended for hole cleaning

• Hard formations may include limestone, anhydrite, hard sandstone with quartic streaks and dolomite. These are rocks of high compressive strength and contain abrasive material. High WOB may be required (e. g. between 6000-10000 lbs/in of bit diameter. In general slower rotary speeds are used (40-100 RPM) to help the grinding/crushing action. Very hard layers of quartzite or chert are best drilled with insert or diamond bits using higher RPM and less WOB. Flow rates are generally not critical in such formations. A more detailed description of formation types and suitable bits is given in Table 2 and 3.

|

|

|

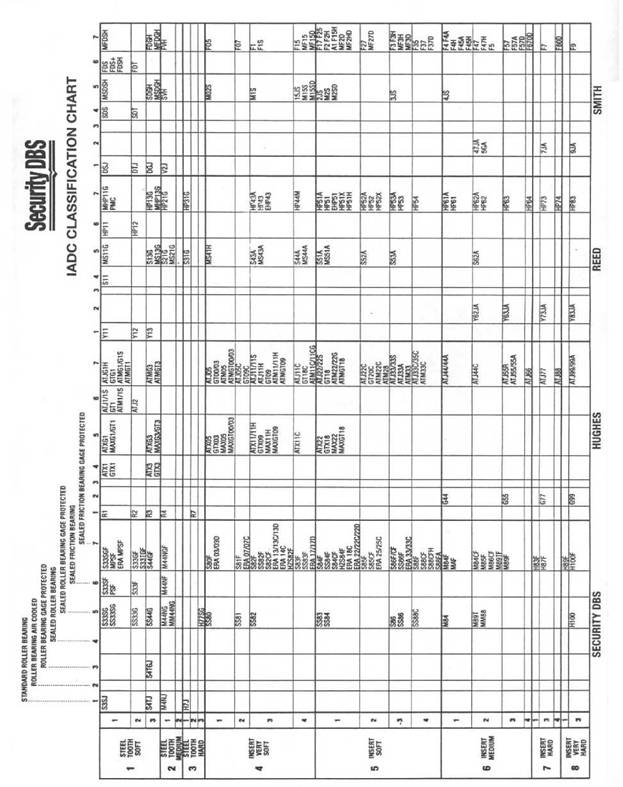

NOTE: Ms chad shows the IADC code relationship between specific bit times. Bit classifications are general and are to be used only as simple guides fSince bit changes are constantly being made, check with a Security DBS representative if you desire a certain type which is not shown.) |

|

|

|

FORMATION |

BIT TYPE |

CUTTING STRUCTURE |

OFFSET AND PIN ANGLE |

BEARING SIZE AND CONE SHELL THICKNESS |

|

SOFT Low compressive strength, high drilla bility, with some hard streaks e. g. clays, soft shale, chalk |

1-1-1 1-2-1 1-2-3 1-3-1 1-3-1 |

long teeth, widely spaced |

maximum offset, pin angle designed for gouging action to give high ROP |

small bearings, thin cone shell to allow for longer teeth |

|

MEDIUM HARD Alternate layers of more consolidated rock, e. g. sandy shales, sand, limestone |

2-1-1 2-1-3 2-3-1 2-3-3 |

shorter teeth, spaced closer together to provide resistance to breakage |

medium offset and pin angle to combine gouging and chipping action |

larger bearings and shell thickness to take heavier WOB |

|

HARD High c ompressive strength, a brasive formations, e. g. dolomite, hard limestone, chert |

3-1-3 3-2-3 3-3-3 |

short stubby teeth, closely packed for crushing action |

minimum offset to give true rolling action i. e. no scraping/gouging only crushing action |

larger bearings, thick shells to take high WOB to drill through hard abrasive, formation |

|

Table 2 Milled Tooth Bits |

|

FORMATION |

BIT TYPE |

CUTTING STRUCTURE |

OFFSET PIN ANGLE |

BEARING SIZE CONE THICKNESS |

|

SOFT Unc onsolidated formations, l ow c ompressive strength e. g. slays, shales |

5-5-7 5-3-7 5-4-7 |

maximum extension of tooth shaped inserts, widely spaced |

pin angle designed to give scraping and crushing action |

small bearings and thin cone shell to accommodate long inserts |

|

MEDIUM Softer segments of hard formations e. g. lime, sandy shale |

6-1-7 6-2-7 |

wedge shaped inserts with reduced extension |

pin angle reduced to give more crushing action, with some gouging effect |

thicker shell to give more protection |

|

HARD Rocks of higher compressive strength e. g. dolomite, chert |

7-3-7 7-4-7 |

wedge shaped inserts closely spaced |

offset reduced to give more crushing/grinding effect, very little scraping |

thicker shell, larger bearings |

|

Table 3 Insert Bits |

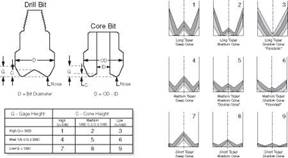

FOUR CHARACTER CLASSIFICATION CODE

|

Cutter Type and Body Material |

Bit Profile |

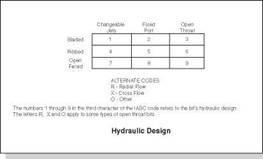

Hydraulic Design |

Cutter Size and Density |

|

First |

|

Second |

|

Ihird |

|

Fourth |

! 1-9

D = Natural Diamond (Matrix Body) M = Matrix Body PDC S = Steel Body PDC T = TSP (Matrix Body)

O + Other

|

Table 4 PDC Bit Selection Chart |

The 1987 IADC Fixed Cutter Bit Classification Standard

|

|

|

|

Density

SIZE Light Medium Heavy

TOC o "1-5" h z Large 1 2 3

Medium 4 5 6

Small 7 8 9

O — Impregnated

CUTTER SIZE NATURAL DIAMONDS NATURAL DIAMONDS

RANGES stones per carat usable cutter height

Large <3 >5/8"

Medium 3-7 3/8" — 5/8"

Small >7 <3/8"

Notes: 1 Cutter Density is determined by the manufacturer.

2 The numbers 1 through 9 and 0 in the fourth character of the IADC code refer to the cutter size and placement density on the bit

Cutter Size and Density

Table 4 (Contd.) PDC Bit Selection Chart

Exercise 1 Selection of a Drillbit

Using the IADC Bit Selection chart (Table 1) select a Type 1 — 2 — 6 bit from each manufacturer listed.