SQUEEZE CEMENTING

SQUEEZE CEMENTING

Squeeze cementing is the process by which hydraulic pressure is used to force cement slurry through holes in the casing and into the annulus and/or the formation. Squeeze cement jobs are often used to carry out remedial operations during a workover on the well (Figure 3). The main applications of squeeze cementing are:

• To seal off gas or water producing zones, and thus maximise oil production from the completion interval

• To repair casing failures by squeezing cement through leaking joints or corrosion hole

• To seal off lost circulation zones

• To carry out remedial work on a poor primary cement job (e. g. to fill up the annulus)

• To prevent vertical reservoir fluid migration into producing zones (block squeeze)

During squeeze cementing the pores in the rock rarely allow whole cement to enter the formation since a permeability of about 500 darcies would be required for this to happen. There are two processes by which cement can be squeezed:

• High pressure squeeze — This technique requires that the formation be fractured. which then allows the cement slurry to be pumped into the fractured zone.

• Low pressure squeeze — During this technique the fracture gradient of the formation is not exceeded. Cement slurry is placed against the formation, and when pressure is applied the fluid content (filtrate) of the cement is squeezed into the rock, while the solid cement material (filter cake) builds up on the face of the formation.

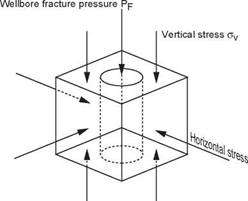

In a high pressure squeeze the formation is initially fractured (broken down) by a solids free breakdown fluid. A solids free fluid is used because a solids laiden fluid such as drilling mud will build up a filter cake and prevent injection into the formation. Solids free fluids such as water or brine are recommended. The direction of the fracture depends on the rock stresses present in the formation. The fracture will occur along a plane perpendicular to the direction of the least compressive stress (Figure 19). In general, the vertical stress, due to the overburden, will be greater than the horizontal stresses. A vertical fracture is therefore more likely. In practice the fracture direction is difficult to predict since it may follow natural fractures in the formation. Since squeeze cementing is often used to isolate various horizontal zones a vertical fracture is of little use (vertical fluid movement is not prevented).

|

|

|

P |

|

F |

|

|

Induced horizontal fracture Induced vertical fracture

PF>°v ; °v<°H1 or °H2 PF>aH1or aH2 ; aH1or aH2< av

Effect of well depth and vertical-horizontal formation stresses on type of hydraulic fracture induced by injected fluid. Horizontal fracture pressure is less than overburden pressure, this is usually the case at depths greater than 3,000 feet.

Figure 19 Horizontal and vertical fracturing

After the formation is broken down a slurry of cement is spotted adjacent to the formation, and then pumped into the zone at a slow rate. The injection pressure should gradually build up as the cement fills up the fractured zone. After the cement has been squeezed the pressure is released to check for back flow. The disadvantages of this technique are:

• No control over the orientation of the fracture

• Large volumes of cement may be necessary to seal off the fracture

• Mud filled perforations may not be opened up by fracturing, so the cement may not seal them off effectively.