TOOL JOINTS

TOOL JOINTS

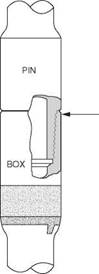

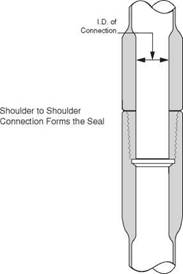

Tooljoints are located at each end of a length of drillpipe and provide the screw thread for connecting the joints of pipe together (Figure 4). Notice that the only seal in the connection is the shoulder/shoulder connection between the box and pin. Initially tool joints were screwed on to the end of drillpipe, and then reinforced by welding. A later development was to have shrunk-on tool joints. This process involved heating the tool joint, then screwing it on to the pipe. As the joint cooled it contracted and formed a very tight, close seal. One advantage of this method was that a worn joint could be heated, removed and replaced by a new joint. The modern method is to flash-weld the tooljoints onto the pipe. A hard material is often welded onto the surface of the tooljoint to protect it from abrasive wear as the drillstring is rotated in the borehole. This material can then be replaced at some stage if it becomes depleted due to excessive wear. When two joints of pipe are being connected the rig tongs must be engaged around the tool joints (and not around the main body of the drillpipe), whose greater wall thickness can sustain the torque required to make-up the connection. The strength of a tool joint depends on the cross sectional area of the box and pin. With continual use the threads of the pin and box become worn, and there is a decrease in the tensile strength. The size of the tooljoint depends on the size of the drillpipe but various sizes of tool joint are available. The tooljoints that are commonly used for 4 1/2” drillpipe are listed in

|

if |

|

|

Table 5. It should be noted that the I. D. of the tooljoint is less than the I. D. of the main body of the pipe.

|

|

|

Cross Section |

|

Figure 4 Tool joint |

|

SIZE |

TYPE |

OD |

ID |

TPI |

TAPE |

THREAD FORM |

|

4 1/2” |

API REG |

5 1/2” |

2 1/4” |

5 |

3 |

V. .040 |

|

4 1/2” |

Full Hole |

5 3/4” |

3” |

5 |

3 |

V. .040 |

|

4 1/2” |

NC 46 (4” IF) |

6” |

3 1/4” |

4 |

2 |

V..038R |

|

4 1/2” |

NC 50 (4 1/2” IF) |

6 1/8” |

3 3/4” |

4 |

2 |

V..038R |

|

4 1/2” |

H.90 |

6” |

3 1/4” |

3 1/2” |

2 |

90° V..050 |

Table 5 API tool joints

Tooljoint boxes usually have an 18 degree tapered shoulder, and pins have 35 degree tapered shoulders. Tool joints are subjected to the same stresses as drillpipe, but also have to face additional problems:

• When pipe is being tripped out the hole the elevator supports the string weight underneath the shoulder of the tool joint.

• Frequent engagement of pins and boxes, if done harshly, can damage threads.

• The threaded pin end of the pipe is often left exposed.

Tool joint life can be substantially extended if connections are greased properly when the connection is made-up and a steady torque applied.